Rosenxt - Linegy

Rosenxt is a forward-thinking technology group

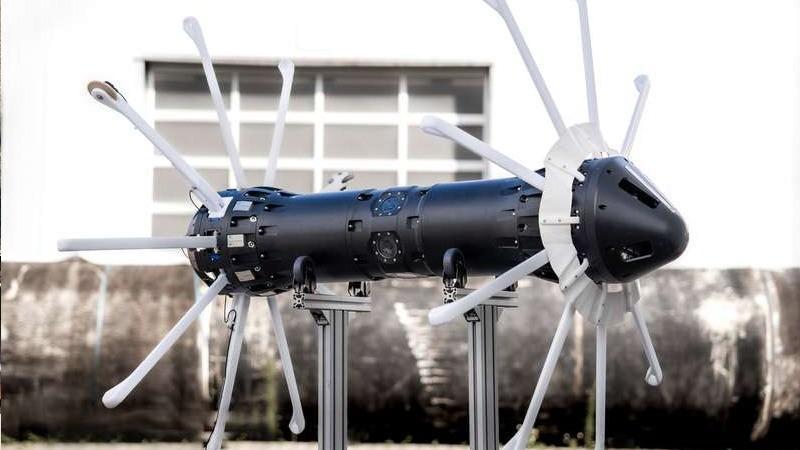

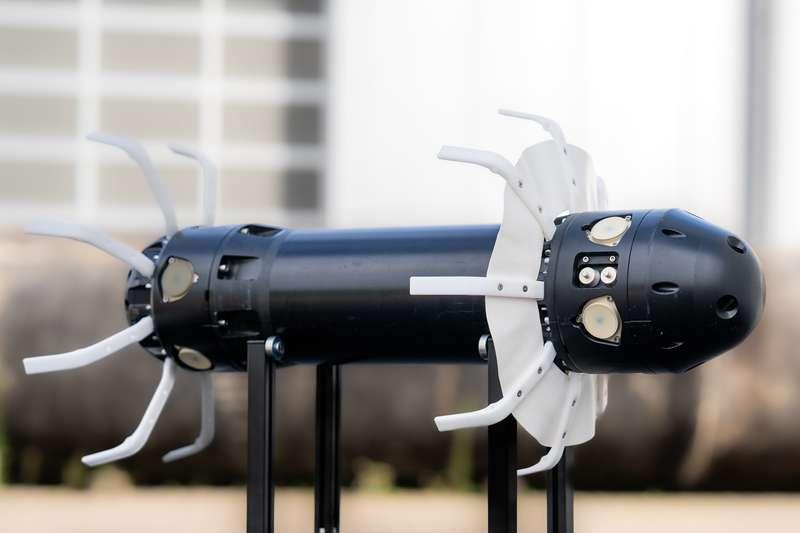

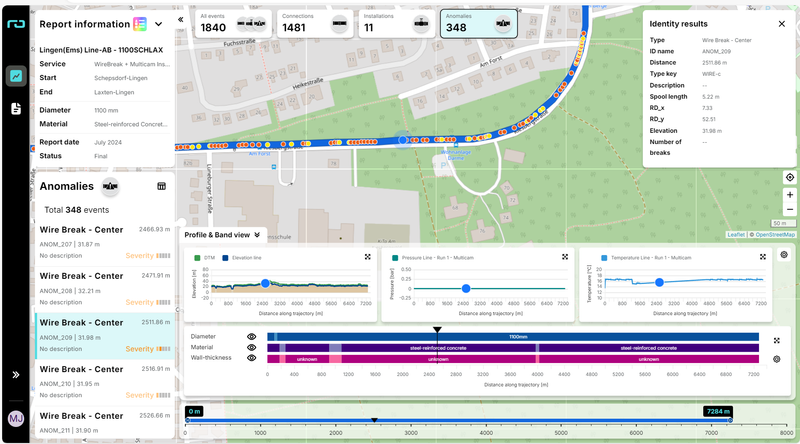

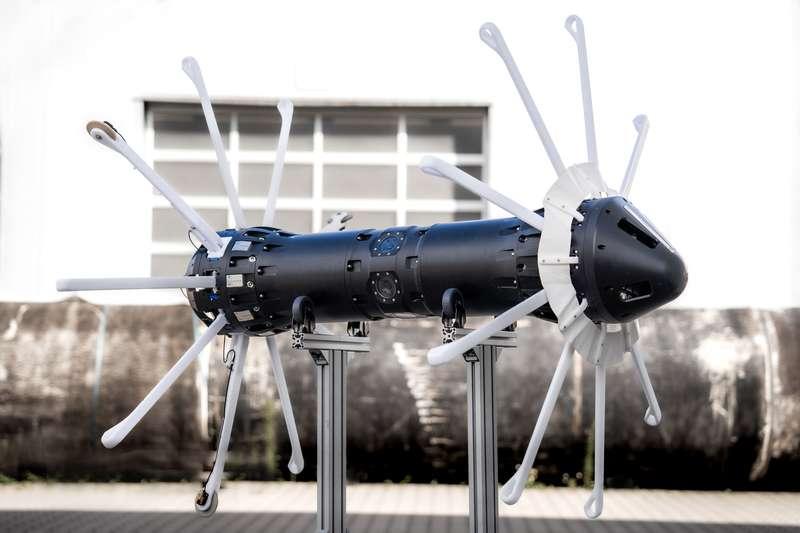

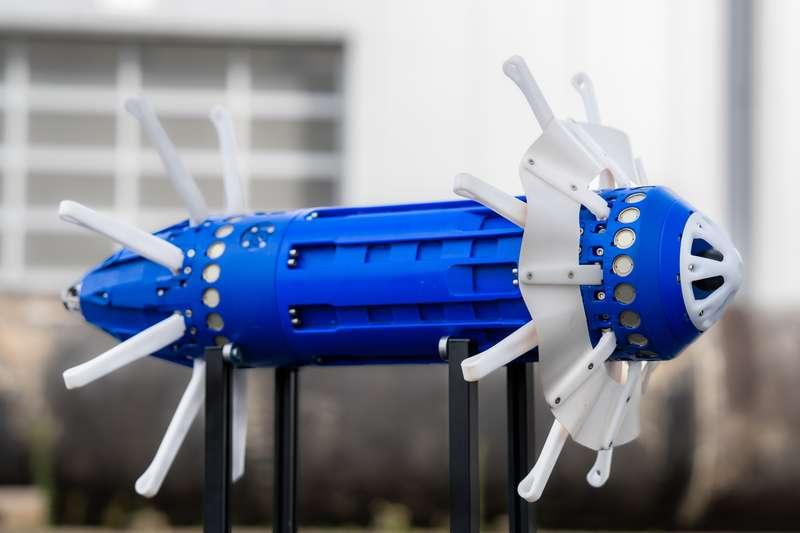

Innovative solutions for securing the supply of water.

Global Water line infrastructure is aging, compromising its integrity and leading to water losses. This requires constant attention. Our holistic approach to Asset Integrity Management ensures the reliability, longevity, and safety of water lines. It includes advanced strategies and techniques, such as risk assessment, regular inspection, condition assessment, proactive maintenance and repair as well as emergency response planning.

STAND NUMBER:

01.235

CATEGORIES:

Products and services

Water Treatment:

Research and consultancy

Wastewater:

Research and consultancy

EVENT:

Aquatech Amsterdam 2025

ADDRESS:

Am Seitenkanal 8 49811 Lingen (Ems) Germany

WEBSITE:

Products