Products

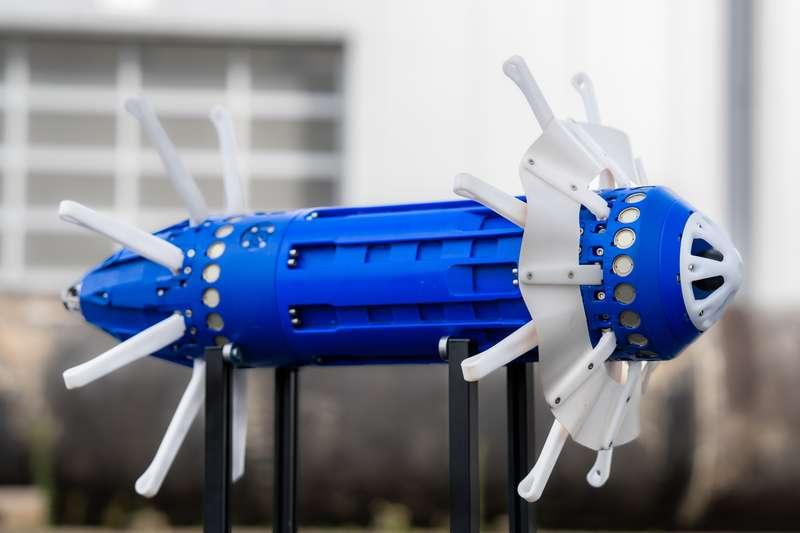

Wire Break Detection

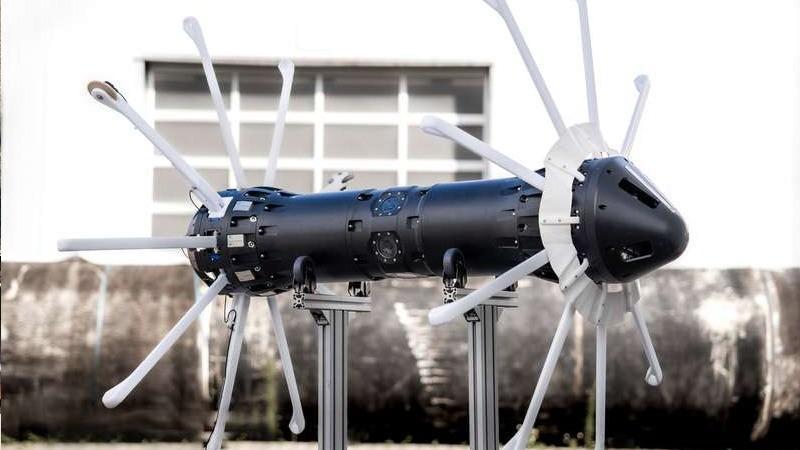

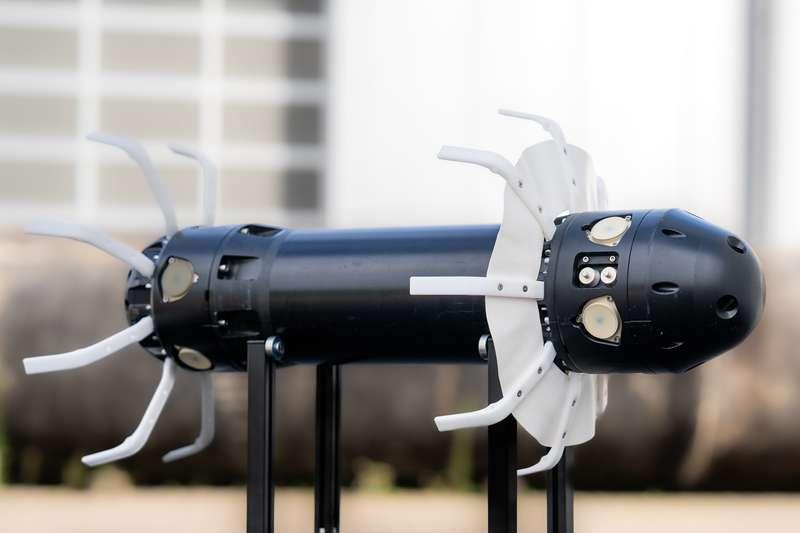

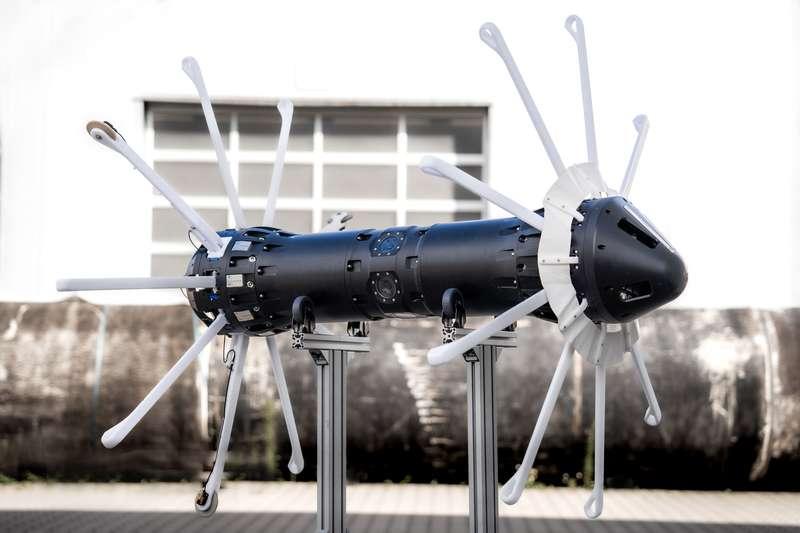

Wire Break Detection with Eddy Current

Our inline wire break detection solution for water lines leverages advanced Eddy Current technology to identify wire fractures within pipeline infrastructure. Eddy Current sensors generate electromagnetic fields that interact with conductive materials, such as metal wires. When a wire is broken, the disruption in the electromagnetic field reveals its location. This non-invasive technique provides real-time, accurate detection of wire breaks without interrupting pipeline operations.

Joint coupling and misalignments

Solution for detecting joint coupling misalignments

Our inline gap and misalignment detection solution for joint couplings in water lines utilizes advanced UT sensors and imaging technology to detect precise alignment and secure connections. This system identifies gaps and misalignments at joint couplings, which are critical points where pipeline sections are joined.

Leaching Detection

Leaching Detection in Asbestos Cement

Our inline leaching detection solution for asbestos cement water lines utilizes advanced UT sensor technology to identify and assess leaching issues. UT sensors emit sound waves that travel through the pipeline wall, detecting variations in material density caused by leaching or deterioration. By analyzing these acoustic signals, the system accurately locates areas where asbestos cement may be compromised.

Air Pockets Detection

Locate the air pockets with hydrophone, UT, and video

Our inline air pocket detection solution uses hydrophones, UT and video technology to accurately locate and assess air pockets within pipelines. Hydrophones detect sound variations caused by air pockets, while UT sensors identify and size trapped air. Video technology visually confirms and maps the air pocket locations with highest precision.

Asset Digitalization

Fast, reliable and efficient Data Management

By leveraging the data gathered from our advanced inspection tools, we convert physical assets into detailed digital representations, which are then stored and managed on secure digital platforms like the Rosenxt Customer Portal. This process not only enhances visibility into the condition of water lines but also facilitates predictive maintenance and decision support by identifying potential issues before they become critical.

Debris & Deposits Cleaning

Tailored cleaning tools for optimal pipeline maintenance

We offer a wide range of cleaning solutions and tools tailored to the specific requirements of pipeline cleaning and maintaining throughput. Our portfolio of special cleaning tools includes both foam pigs with maximum passage capabilities and rigid cleaning tools with excellent cleaning properties.

Deformation & Ovality Detection

In-line inspection for pipeline deformation detection

Our in-line inspection solution provides detailed ID and ovality profiles using multiple calipers or UT sensors. It identifies and measures geometric deformations that might affect pipeline integrity. Additionally, it detects spalling, obstacles and installations such as valves, tees, flanges, welds and couplings, ensuring a thorough assessment and effective maintenance of pipeline conditions.

Corrosion Detection

Corrosion Detection with advanced UT sensor technologies

Our inline corrosion detection solution for water lines utilizes advanced UT sensor technology to identify and assess general corrosion. UT sensors arrays emit sound waves that travel through the pipeline wall, detecting variations in material thickness caused by corrosion or deterioration. By analyzing these acoustic signals, the system accurately locates areas where the pipe material may be compromised due to corrosion.

Remote Leakage Sensing

Early Leak Detection for Efficient, Cost-Effective Maintenance

Our satellite-based solution for detecting leaks along a water lines uses high-resolution imagery and sensors to monitor the pipeline's path. It analyzes thermal, optical, and radar data to detect anomalies like unusual moisture levels or temperature changes, indicating potential leaks.

Leakage Detection

Leak Detection Reduces Operational Costs

Our inline leak detection solution utilizes advanced hydrophone technology to identify leaks with high precision. The hydrophone, sensitive to acoustic signals, detects the distinct sound patterns generated by leaks in the pipeline. By continuously monitoring the internal environment, it can pinpoint leak locations, even at early stages, minimizing the risk of significant damage.

Mapping & Movement

Track your pipeline

By using a high-end inertial measurement unit (IMU) we precisely measure angular changes and accelerations in the X, Y, and Z axes as our inspection tool navigates through the water line. This technology provides accurate pipeline routing information even when original maps are unavailable or inaccurate. It identifies pipeline centerlines with precision and delivers data that integrates seamlessly with our Rosenxt Customer Portal or your in-house GIS systems.

Inline video inspection

360° Multi-Camera Inspection for Comprehensive Pipeline Evaluation

Our inline multi-camera video inspection solution offers a comprehensive evaluation of water lines by capturing high-definition footage from multiple angles simultaneously. This advanced system employs several cameras strategically positioned within the pipeline, providing a full 360-degree view of the internal surfaces. The multi-camera setup allows for real-time detection of anomalies that single-camera systems might miss.

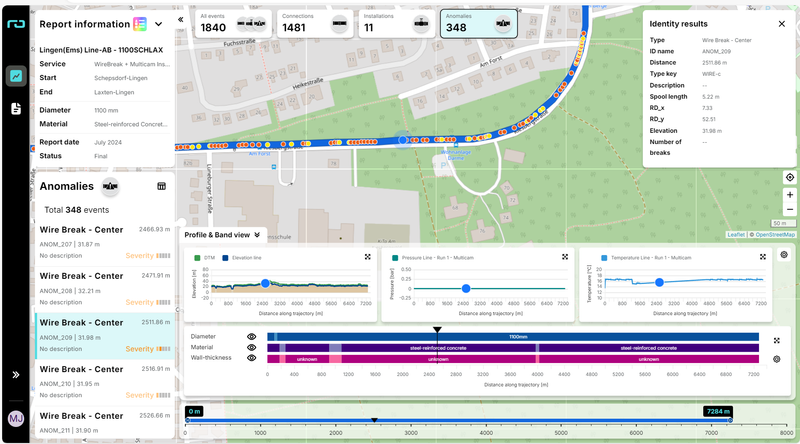

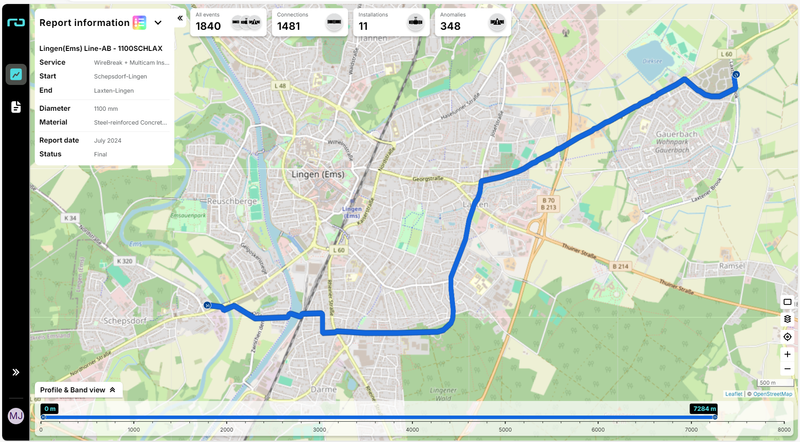

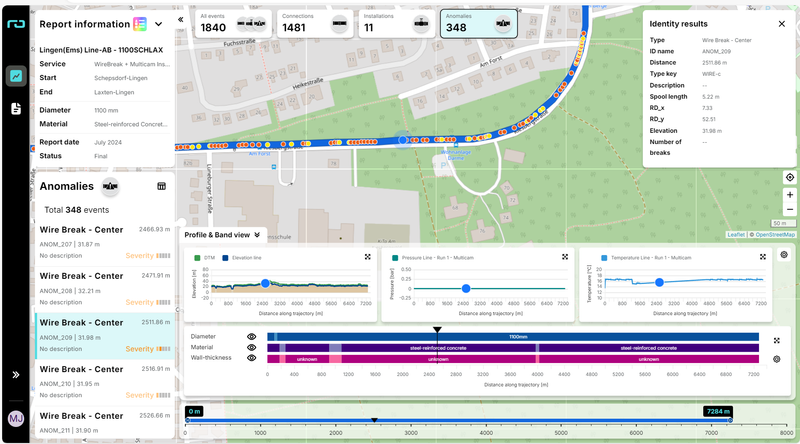

Interactive Inspection Reports

Streamlined Inspection Reporting with Digital Platform

Our platform-based solution for reporting information from water line inspections streamlines data collection, analysis, and sharing. By integrating inspection results into a centralized digital platform, operators can easily interact, access and manage detailed reports, images and analytics in real-time. This approach enhances collaboration, enabling quicker decision-making and more effective maintenance strategies.

Wire Break Field Verification

Identify wire fractures

Our inline wire break detection solution for water lines leverages advanced Eddy Current technology to identify wire fractures within pipeline infrastructure. Eddy Current sensors generate electromagnetic fields that interact with conductive materials, such as metal wires. When a wire is broken, the disruption in the electromagnetic field reveals its location. This non-invasive technique provides real-time, accurate detection of wire breaks without interrupting pipeline operations.