GKD

GKD – GEBR. KUFFERATH AG

GKD Group

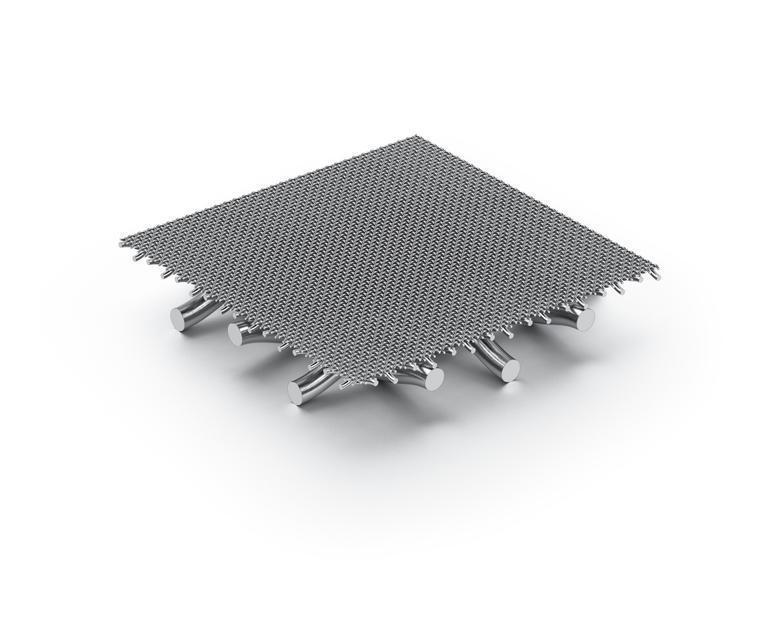

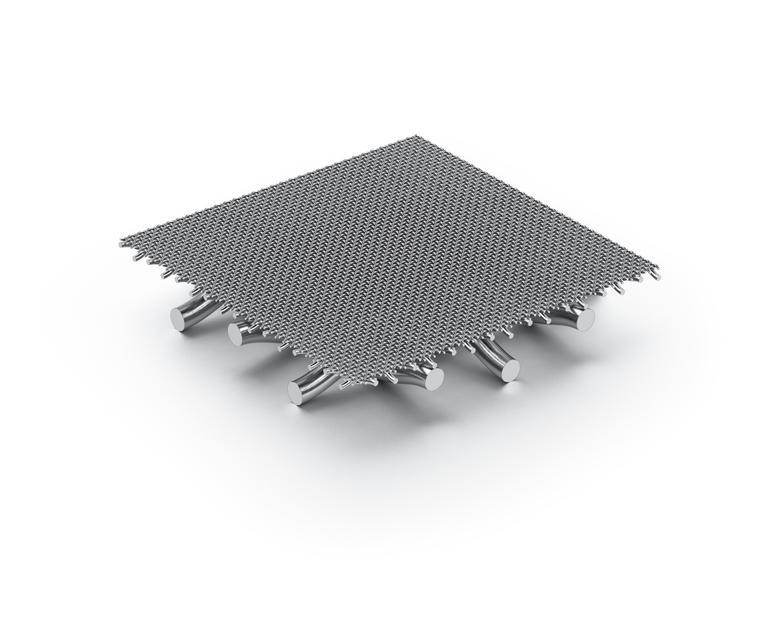

As a privately owned technical weaving mill, GKD – Gebr. Kufferath AG is the global market leader for metal mesh, synthetic mesh, and spiral mesh solutions. Since 1925, the company has provided solutions for a large number of application areas in the fields of Architecture & Design, Industry & Filtration, Process Belts, and Capital Equipment. In all of these sectors, GKD strives to make a key contribution to creating a healthier, cleaner, and safer world.

STAND NUMBER:

11.308

CATEGORIES:

Trading regions

Africa:

Algeria, Angola, Benin, Botswana, Bouvet Island, Burkina Faso, Burundi, Cameroon, Cape Verde, Central African Rep, Chad, Comoros

Americas:

American Samoa, Anguilla, Antigua & Barbuda, Argentina, Aruba, Bahamas, Barbados, Belize, Bermuda, Bolivia, Brazil, Canada

EVENT:

Aquatech Amsterdam 2025

ADDRESS:

Metallweberstrasse 46 52353 Dueren Germany

WEBSITE:

Products

Downloads

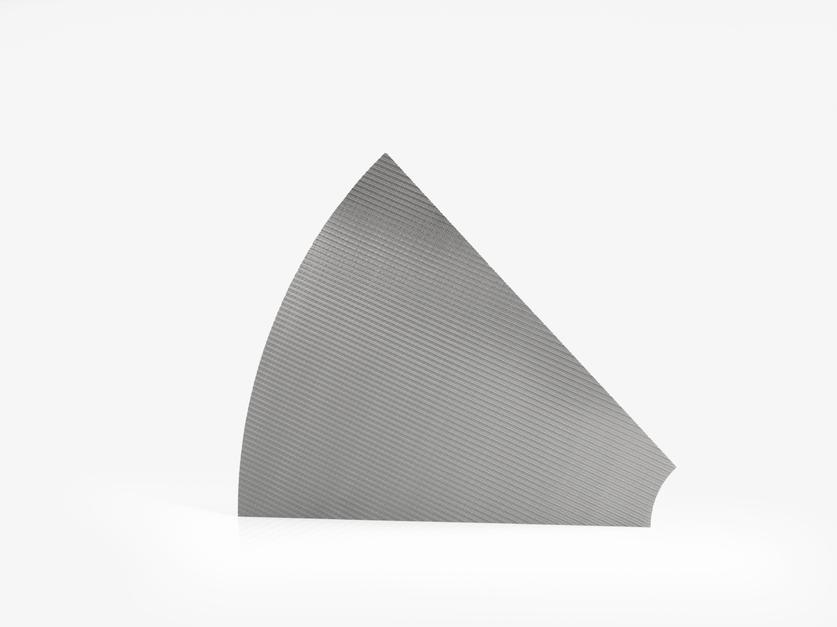

GKD CAPTURION: Filters for tire abrasion

The patent-pending CAPTURION street drain filter combats microplastic pollution, especially at urban hotspots such as major road intersections. Thanks to the filter’s construction and the mesh properties, it has a high capacity and is ideal for cleaning during routine road maintenance.

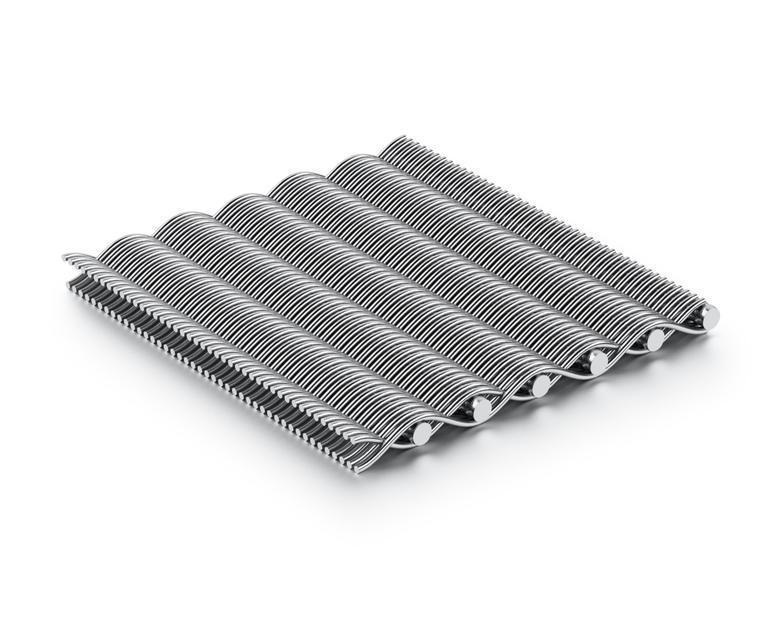

Process belts for sludge dewatering and drying

Efficient sludge dewatering with process belts produced from synthetic mesh