Products

CAPTURION

GKD’s new CAPTURION is the year-round road drainage filter system that can be integrated into any existing infrastructure.

Tire wear from road traffic is one of the main sources of microplastics. The patent-pending CAPTURION street drain filter combats microplastic pollution in water, especially at urban hotspots such as major road intersections. GKD took the specific requirements of local authorities into account during development. Thanks to the filter’s construction and the mesh properties, it has a high capacity and is ideal for cleaning during routine road maintenance.

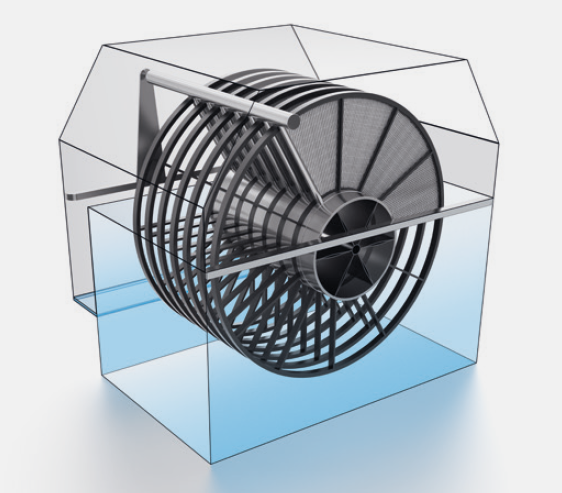

Vortex Separation Unit

The Vortex Separation Unit uses vortex flows to efficiently separate particles, fibers, and other contaminants from both liquids and gases. This technology is inspired by biomimetic principles, similar to manta rays that use water vortices to filter particles effectively. The unit is versatile and suitable for applications in water and air purification as well as in industrial processes.

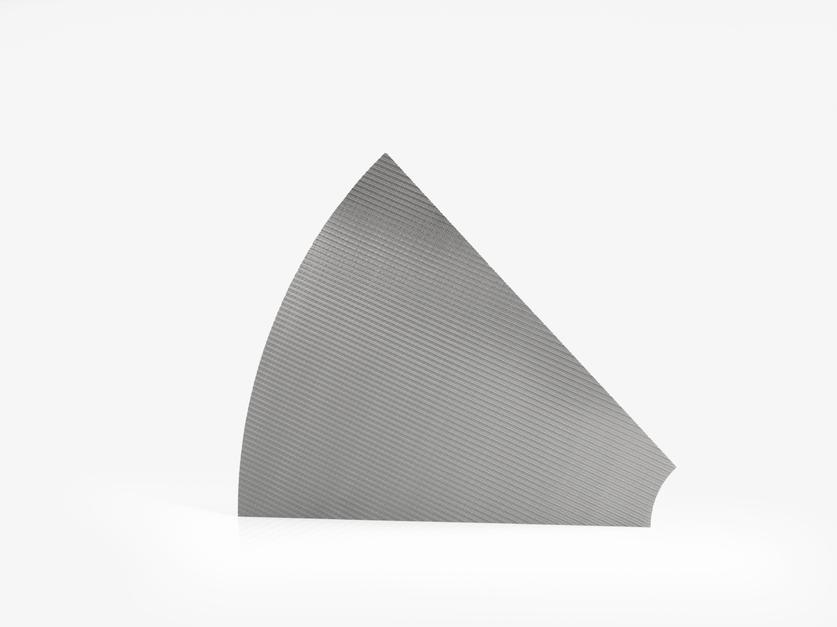

Mesh segments

Mesh segments are produced as semi-finished products for further processing in filters or filter systems.

The mesh segments can be individually manufactured with our plasma and laser cutting systems. These allow complicated geometries to be cut with high precision. At the same time, the segments get secured edges. The systems can produce segments in dimensions of up to 5 * 2 m.

Larger segment sizes can be produced using conventional cutting technology up to diameters of > 5 m.

Filter cartridges

Filter cartridges are produced in a wide range of variants regarding their mechanical dimension, compressive strength and retention rate.

The optimum filtration mesh is selected on the basis of the respective process requirements. Mechanical dimensions and compressive strengths are defined on the basis of existing filter systems. Filter cartridges can also be produced as backwashable elements. Filtration meshes and cartridge designs are optimally matched to one another, particularly for OEM applications. Mesh production and the following manufacturing steps can be set up as a homogeneous production chain.

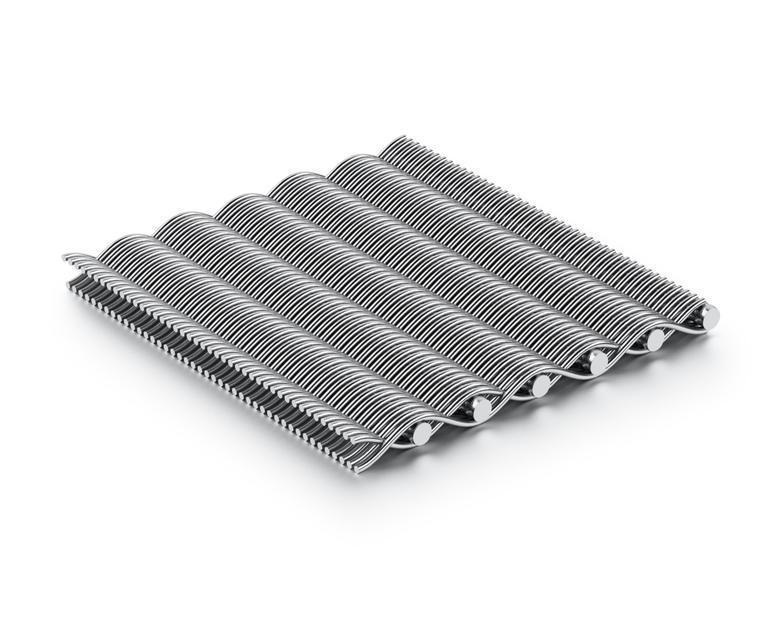

Optimized dutch weave

Optimized plain dutch weave is a further development of plain dutch weave for ultrafine filtration.

It is made up of a small number of thick warp wires and many thin weft wires. Due to the larger number of fine weft wires, these are interlocked during the production process. The result: slit-like openings with very small pore sizes, which ensure a high level of permeability. Like plain dutch weave, optimized plain dutch weave offer a particularly high mechanical load-bearing capacity. One of the most frequent applications for this product is the filtration of fresh water and sewage.

Porometric

The new POROMETRIC high-tech filtration mesh

At a constant volume flow, the higher porosity of the Porometric filtration mesh resulting from its design reduces the highest, local pore velocity by up to 40% compared to conventional filtration meshes. The lower maximum pore velocity results in lower wear of the filter material through particles. At the same time, however, the flow rate increases considerably when using this new mesh type.

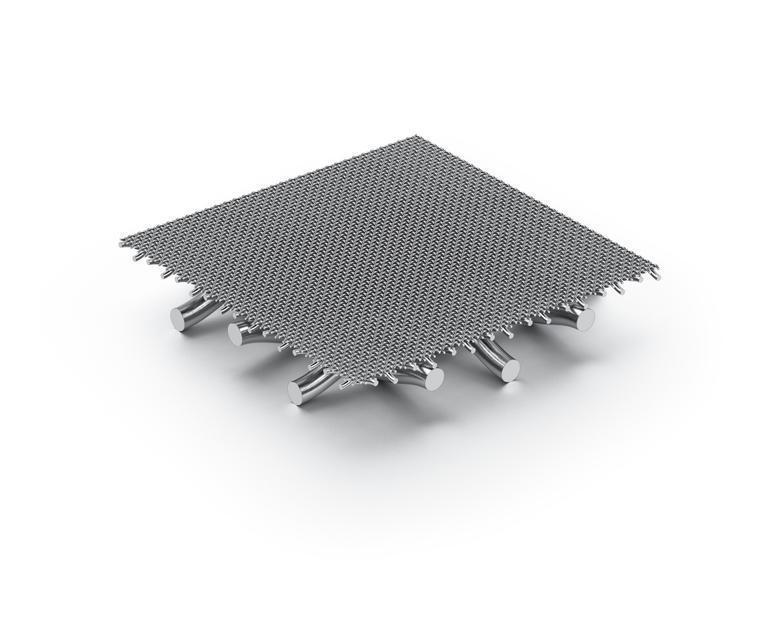

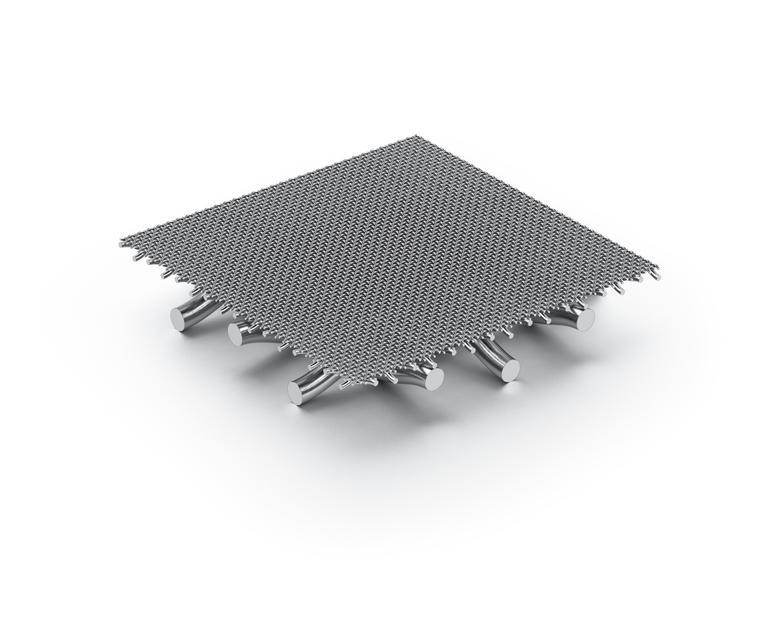

GEKUPLATE

GKD wire mesh laminates (GEKUPLATE) or sintered plates made of mesh are fine filter media for mechanically demanding tasks.

They exhibit the same filtration properties as individual wire mesh plies of the same fineness. By sintering multiple layers of mesh, highly robust structures are created. These are more stable than single layers and can therefore be subjected to greater mechanical loads. There is a varied and virtually limitless array of possible layered combinations of different meshes, thus allowing us to meet even the toughest customer requirements.

Aquaculture – Filters for fish farms

GKD offers various metal meshes for filtration applications in aquaculture.

In the large tanks of recirculating aquaculture systems (RAS), drum and disk filters are used to clean the water of feed residue and excrement so that it can be reused.

POROMETRIC mesh has filtration rates of 20-100 μm and an optimized weave structure that enables almost 90 percent porosity and unsurpassed flow rates. In comparative tests conducted by the Karlsruhe Institute of Technology (KIT), it also demonstrated the best cleaning behavior – with the same low backwashing rate.

Agriculture – Filters for irrigation systems

Greater performance for agriculture - The wire mesh laminate GEKUPLATE has extremely strong structures thanks to the sintering of several mesh layers.

Both organic and inorganic particulate can clog irrigation sprayers during the irrigation of agricultural products. This can severely compromise the performance of an irrigation system, increase maintenance costs, and negatively impact harvests. GKD filtration mesh and elements are the solution and ensure longer maintenance intervals and increased performance and efficiency in filter systems.

Dishwashers – Mesh for washing-up water

Our stainless steel square mesh offers a solution to the specific challenges of appliance filters.

GKD manufactures specially developed metal mesh for dishwasher filters that is characterized by durable corrosion resistance, excellent workmanship, and easy maintenance. GKD’s stainless steel square mesh offers a solution to the specific challenges of appliance filters.

The precision of the mesh pattern of the stainless steel square mesh is ensured through the use of optical measuring methods. This allows even minimal deviations to be detected.

Tumble dryers – Vortex unit for dryers

Improved air circulation, fewer particles

The vortex-based separation unit from GKD effectively captures fluff and particles and optimizes air circulation in the dryer. Improved airflow distributes the heat more evenly and reduces the drying time of the laundry. This reduces energy consumption and operating costs. At the same time, our technology minimizes the risk of dryer fires by preventing the accumulation of flammable lint.

Washing machines – Filters for washing water

The microplastic filters with the GKD mesh can be integrated into modern washing machines or used as a retrofit option for existing models.

Fiber abrasion is responsible for 35 percent of global marine pollution caused by microplastics. GKD has developed a mesh for microplastic filters designed for washing machines to combat this problem. The filter removes up to 90 percent of microplastic fibers with a size of up to 50 μm from washing machine wastewater by combining vortex technology and POROMETRIC mesh.

Domestic water supply – Unit for household connections

GKD has developed a vortex separation unit with POROMETRIC mesh, which is installed at the domestic water connection.

By using vortex flows, the innovative system effectively separates dirt and deposits from the domestic water supply. The filter’s self-cleaning mechanism is unique: a simple backwash process, which can be triggered both manually and automatically, removes and drains impurities from the filter without having to replace the filter element.

Domestic water supply – Treatment of drinking water

To prevent contamination with these tiny plastic particles, solids and sediments, the use of special filter solutions is recommended.

The metal filter media developed by GKD are characterized by their extremely fine mesh pores, which are four times thinner than human hair.

In addition to microplastics, grains of sand and rust particles also pose a risk to drinking water, as they can damage water systems, pipes, and appliances. To avoid this, water pre-filters specially designed for drinking water systems are used. To this end, GKD offers solutions made of high-quality stainless steel, such as the optimized dutch weave.

Sewage plants – Filters for micro sieving

Effective sewage treatment

Unfiltered wastewater carries countless solids and bacteria. That’s why filtration in municipal sewage plants plays a crucial role in the purification of wastewater before it is returned to the environment. Screen and filtration meshes from GKD are used in many areas of mechanical microfiltration of wastewater and significantly reduce water pollution. For example, our optimized dutch weaves can be found in drum or disk filters in sewage treatment plants.