Products

GROUNDWATER REMEDIATION AND PURIFICATION

SPECIALTY RESINS- GROUNDWATER REMEDIATION AND PURI

Heavy metals – Selective removal of copper, zinc, nickel, lead, tin, cadmium, iron and other heavy metals can be done with special chelating resins.

Fluoride – Fluoride can be removed by either Tulsion® fluoride selective cation exchange resins or Tulsion® specialty chelating resins.

Boron – Speciality chelating resins for selective removal of boron.

Mercury – Selective removal of mercury with specialty chelating resin by chelation mechanism.

Nitrate and Sulphate – Specialised strong base anion resins a

POLYMERIC CATALYST RESIN

SPECIALTY RESINS- POLYMERIC CATALYST RESIN

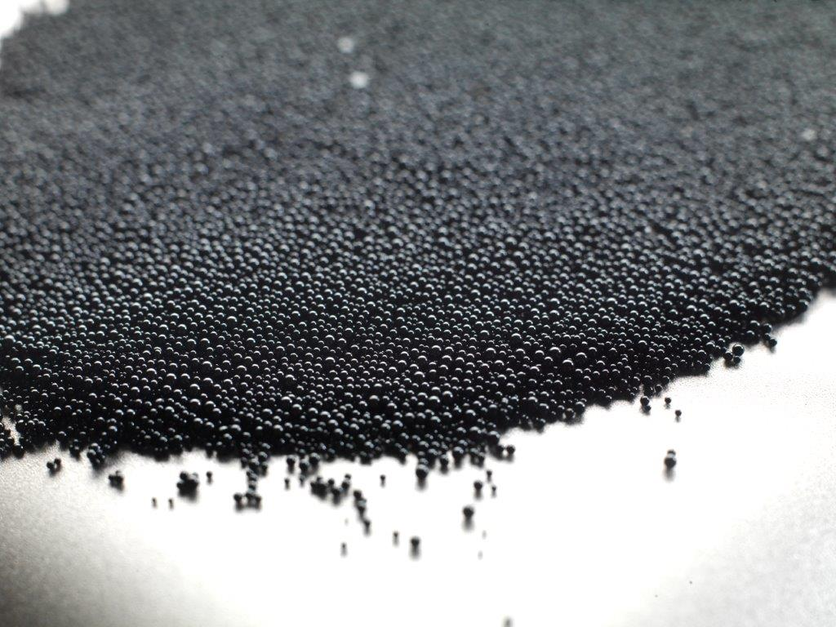

Catalyst resins are insoluble, polymeric beads which are used in different industries for various processes. Thermax offers specialty Tulsion® range of polymeric catalysts that are available in hydrogen and hydroxyl form. The hydrogen form catalyst is used for reactions that are normally catalysed by mineral acids, whereas the catalyst in hydroxyl form is used for base catalysed reactions.

Tulsion® resins are widely used as catalysts in heterogeneous catalysis for providing excellent kinetic performance.

RECOVERY AND PURIFICATION

SPECIALTY RESINS- RECOVERY AND PURIFICATION

Tulsion® resin is very efficient for the selective adsorption and exchange of valuable substances from aqueous solution that are present in traces. To recover these valuable substances in purifies form common regeneration methods are used.

Applications:

Gold recovery

PGM-platinum, palladium, gold, rhodium

Recovery and removal of uranium

Removal and recovery of amino acids like lycin, glycin, organin, etc., from aqueous streams by Tulsion® resin

Phenol recovery from aqueous solution

Removal and recove

ADSORBENT RESIN

SPECIALTY RESINS- ADSORBENT RESIN

Tulsion® polymeric adsorbents can be used in columns with repeated exhaustion and regeneration cycles in both up-flow and down-flow operations. They have specifically designed pore size, surface area and particle size, and qualify the stringent limits of free salts and metals.

Tulsion® speciality adsorbents are of two types:

Polystyrene-based – These adsorbents are used to adsorb hydrophobic (non-polar) solutes from polar solvents. Selectivity and extent of adsorption of a solute increase as hydrophobicit

CHELATING RESIN

SPECIALTY RESINS- CHELATING RESIN

Tulsion® chelating resin have functional groups like iminodiacetic-acid, phosphoric acid, thiouronium, thiol which acts as a mono-dentate, di-dentate and tri-dentate, tetra-dentate ligand respectively to form a metal chelate with different metals. This durable macroporous resin can selectively remove metals from aqueous and organic solutions at varied pH. Regeneration of this resin can be done with the help of basic acids and bases, making it most cost effective method. Chelating resins are most useful in t

RESIN FOR FOOD AND BEVERAGES

SPECIALTY RESIN FOR FOOD AND BEVERAGES

No matter what food we eat; baked, fried, roasted, steamed, processed, frozen or canned, in today’s time people are choosing high quality of food available. And for transforming food and beverages from the raw material into high quality processed food, an effective food grade resin has a vital role to play. Either it is juice de-acidification, de-bittering, sugar decolourization and purification, etc. Tulsion® resin is taking care of all. These resins are specially manufactured in a clean and hygienic envir

WASTE WATER TREATMENT RESIN

WASTE WATER TREATMENT RESIN

Ion exchange resin is used for the removal of contaminants from the waste water so that it can be reused in the process cycle. The effluent generated from various industries can be treated using resins. These resins can be used in conjunction with ETP & STP plants for the treatment of the water.

RESIN FOR OTHER POTENTIAL APPLICATIONS

RESIN FOR OTHER POTENTIAL APPLICATIONS

MEG cycle water purification – Purification cycle water loop by Tulsion®/Tulsimer acclaimed resin.

Biodiesel purification – Biodiesel (methyl ester) is purified through specialised Tulsion® resin column/s to remove impurities like glycerine, soaps, free fatty acids and traces of catalyst, along with ionic salts to produce pure biodiesel.

Amine purification – Amine solvents are used to remove acidic components like hydrogen sulfide and carbon dioxide from the feed gas of the refineries, natural gas plants

SOFTENING

INDUSTRIAL WATER TREATMENT RESINS- SOFTENING

Water softening is the removal of hardness from the water which is caused mainly due to the presence of calcium and magnesium ions. Hard water is formed when water percolates through deposits of limestone and chalk which are largely made up of calcium and magnesium carbonates. Hard drinking water may have moderate health benefits, but can pose serious problems in industrial settings, where water hardness is monitored to avoid costly breakdowns in boilers, cooling towers, pipelines, pumps and other equipment

DEMINERALISATION

INDUSTRIAL WATER TREATMENT RESINS- DEMINERALISATIO

Demineralisation is the process of removing most of the mineral content from raw water. In general, demineralisation of water is carried by first passing water onto a Tulsion® cation exchanger in the hydrogen form, followed by Tulsion® anion exchanger in hydroxyl form, in two-column process. Cation exchange resin will replace the positively charged ions retaining H+ ions while anion exchange resin will replace the negatively charged ions retaining OH- ions. This combination will result in production of de-m

DE-ALKALISATION

INDUSTRIAL WATER TREATMENT RESINS- DE-ALKALISATION

Alkalinity is due to the presence of dissolved bicarbonate (HCO3), carbonate (CO3) and hydroxyl (OH) ions in water. The alkalinity needs to be removed and monitored to prevent scale and corrosion. Raw water having high alkalinity, even after softening, causes foaming and carryover of solids that leads to embattlement of boiler steel. The decomposition of bicarbonates due to heat produces CO2, which causes corrosion.

MIXED BED RESIN

INDUSTRIAL WATER TREATMENT RESINS- MIXED BED RESIN

Tulsion® Mixed Bed (MB) resins are a mixture of cation and anion exchange resins. These heterogeneous resins are used as polishers to obtain high purity water, which is required for boiler feed for high-pressure boilers, electronics and electrical discharge cutting machines, glass window washing and pharmaceutical applications. Tulsion® MB resins can be supplied in highly regenerated, premixed conditions for use in dye applications. They are also available as highly regenerated cation and anions for use in

CONDENSATE POLISHING

INDUSTRIAL WATER TREATMENT RESINS- CONDENSATE POLI

Condensate Polishing is a process deployed to remove contaminants from condensate streams like steam, turbine and process condensate, before it is returned to the boiler/heat exchangers. It is highly important to remove traces of soluble inorganic impurities present in the feed water, as they may get concentrated within the system.

Ion exchange resins used in condensate polishers mainly serve two purposes:

Removal of suspended solids by filtration more

Removal dissolved solids by ion exchange

Tulsion® Mix

NUCLEAR INDUSTRY

INDUSTRIAL WATER TREATMENT RESINS- NUCLEAR INDUSTR

Water treatment in a nuclear power plant is extremely critical as it correlates to various issues associated with equipment corrosion, scaling, their safety and maintenance, corrosion of reactor fuel rods, radioactive contamination, etc. Therefore, it is important to use the finest quality of ion exchange resins, which can provide the right feed water that maintains high level efficiency all over the plant.

Tulsion® nuclear grade resins are manufactured and processed specially to achieve exceptionally high

ULTRAPURE WATER

INDUSTRIAL WATER TREATMENT RESINS- ULTRAPURE WATER

Ultrapure water (also UPW or high-purity water) is water that has been purified to uncommonly stringent specifications. Ultrapure water is a commonly used term in the semiconductor industry to emphasize the fact that the water is treated to the highest levels of purity for all contaminant types. Its include, organic and inorganic compounds; dissolved and particulate matter, volatile and non-volatile, reactive and inert, hydrophilic and hydrophobic, and dissolved gaseionics. The production in the electronics