Australian utility, Water Corporation, has recently completed the installation of an initial four Vortex Powered Aeration™ (VPA) units, produced and supplied by Irish company Vortech Water Solutions, helping to future-proof treatment capacity, reduce ongoing operational costs and ensure process reliability and stability at its East Rockingham facility.

East Rockingham had a requirement to increase its wastewater treatment capacity to become roughly a 250,000-population equivalent, or 30 million litres of wastewater per day (ml/d). The VPA’s have been installed in the first of two oxidation ditches, with another four to follow in the second ditch in the coming months.

Water Corporation chose the VPA units because of their ease of installation, operation and reduced ongoing maintenance and energy costs. Providing fine bubble aeration, the VPA units can be deployed in a matter of days, where typically it takes weeks to fit and commission traditional fine bubble diffused aeration (FBDA) systems.

Units sit above the waterline, rather than being bolted to the bottom of the tank, six meters below the water surface. Operation and access from above the waterline result in both higher oxygen transfer efficiencies in shallow tanks, lower operating costs, and provide easy operator access to the single moving component that may need to be accessed in the future.

No more need for scaffolding, escape sets, forced ventilation and risky confined space entry for operators - McConomy

John McConomy, commercial director, Vortech Water Solutions, told Aquatech Online: “The VPA is mounted above the waterline, which means you don’t need to drain and de-sludge the system to access the fine bubble aeration equipment. No more need for scaffolding, escape sets, forced ventilation and risky confined space entry for operators, the VPA is easily accessed without the major inconveniences associated with traditional fine bubble aeration.”

Reliability and consistent performance are other key advantages; traditional bubble systems typically use small perforations that are subject to fouling from day one, which impairs performance over time and leads to increasing energy consumption year on year. VPA’s use a pump that has been on the market for over 20 years, and a clever, trouble-free vortex to introduce bubbles into the wastewater. This ensures performance remains consistent.

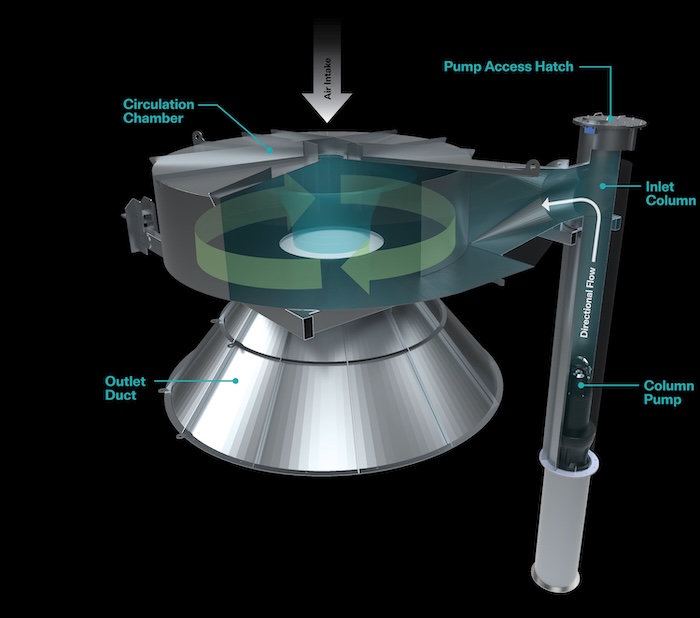

Vortex aeration works using the principles of fluid dynamics by harnessing cyclonic flow. VPA technology pumps wastewater above the top water level, where a cyclone draws in ambient air to oxygenate and mix the reactor, directly and efficiently.

The push-pull water flow of the VPA system, high-speed jetting of water back into the tank and pulling (uniquely due to the pumping effect) of water from below water, mixes and can keep solids in suspension (MLSS). Where traditional aeration pushes bulk ‘air to water’ using blowers and air piping, the VPA brings ‘water to the air’.

McConomy explained further: “Vortex aeration simplifies operations, lowers costs and has a lifespan twice that of conventional technology. The positive feedback from our customers, lower energy bills, fewer maintenance calls, and safer operation, prove its value in the field”.

Vortex aeration simplifies operations, lowers costs and has a lifespan twice that of conventional technology - McConomy

In this way, the VPA effectively mimics the actions of a cascading river, ensuring all of the water flowing through the vortex is exposed to oxygen before being dispersed back into the tank for further mixing.

Water depth is not an issue because aeration occurs above the water, not in it. The VPA unit needs less than two metres of water depth to provide the performance that traditional FBDA systems deliver in six metres of water. The flow of fluid through the VPA unit is easily controlled to limit dissolved oxygen levels and oxygen transfer. Anoxic conditions can also be achieved and maintained using the system’s cyclonic pulse feature.

The only moving part of the VPA is a submersible, robust column pump, positioned so that maintenance can be performed without entering or draining the tank. The simplicity of the design means that repairs take only minutes and retrofitting is a relatively simple operation.

This makes the system easier to maintain than submerged fine bubble systems, which also require blowers and valves, as well as complicated mechanical aeration devices, which often have high-inertia impellers, rotors, extended spindles and gearboxes.

McConomy added: “If someone had told me 20 years ago that a high-efficiency fine bubble aeration system could be maintained or switched out completely in only a few hours, without getting your hands wet, I would have said it was impossible. But today I know it’s not; this technology will assist maintenance crews across the globe and in removing the need for confined space entry, thankfully, end users can now also provide a safer working environment on site.”

This technology will assist maintenance crews across the globe and in removing the need for confined space entry - McConomy

Installation typically takes no more than two days per unit, without any disruption to process treatment.

The VPA is versatile; it is capable of treating harsh industrial loads and, importantly, holds a high alpha factor even in high mixed liquor concentrations where traditional diffusers may prove impractical or ineffective.

The VPA units can offer energy savings over traditional aeration methods, even in challenging conditions. This can prove beneficial to end users, especially when we note aeration on treatment facilities often consumes up to 70 per cent of a wastewater plant’s energy use.

Biological treatment is the foundation of modern wastewater systems. It relies on natural microbes to break down pollutants, turning wastewater into cleaner, safer water. Aeration, adding oxygen to the process, is key, helping these microbes thrive and accelerate the breakdown of organic matter.

As communities face stricter environmental standards, biological systems must adapt to changing treatment goals, from removing nutrients to improving overall water quality. The future of wastewater infrastructure depends on technologies that are simple, robust, and easy to control, ensuring reliable performance, even as conditions and requirements change.

Traditional aeration systems are efficient but can be complex, offering maintenance challenges to wastewater treatment plant operators. In 2016, Dr Sean Mulligan, Vortech’s founder and CEO, began exploring the idea for vortex aeration, based on his work designing the large-scale vortexes used in deep sewer systems.

Research showed that vortices can produce the fine bubbles required in wastewater aeration, without the problems associated with traditional systems, such as fouling and maintenance. Mulligan’s research led to the world’s first Vortex Powered Aeration (the VPA units) system, which was commercially installed in 2020.