Researchers use sludge to create stronger sewer pipes

Australian researchers are using wastewater treatment sludge to build corrosive-resistant pipes for the country’s sewer network that have the potential to significantly reduce the cost of repairs each year.

The scale of sewage networks is immense; for example, South Australia maintains over 9,300 km of sewage piping. Globally, the combined length of these networks is estimated to circle the equator multiple times, and so anything that can reduce the frequency and cost of repairs and replacement would have many benefits.

The problems with concrete sewer pipes

Under ideal conditions a concrete sewer pipe has the potential to last for anywhere between 50 and 100 years. Concrete is popular because materials are readily available – cement, water, aggregates, such as sand and gravel – and it is a strong material that retains its shape well and offers good hydraulic performance.

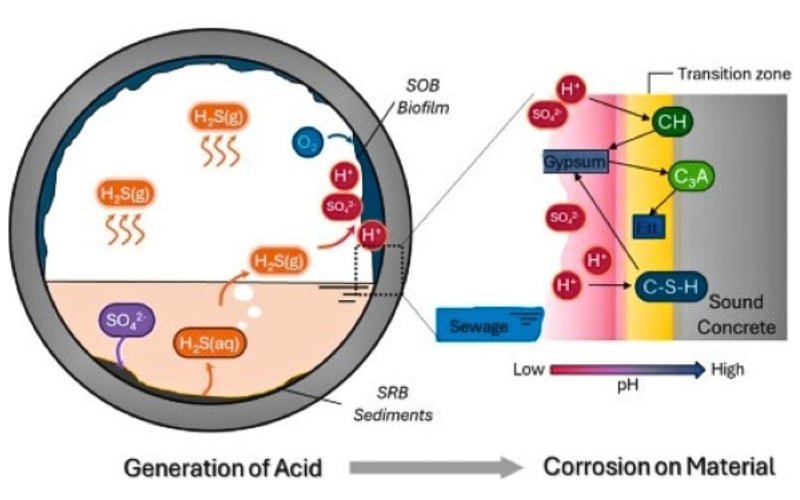

However, if the pipes are laid incorrectly, they can be prone to cracking, especially in areas where the ground is subject to movement. Despite their longevity in ideal conditions, concrete sewer pipes are also prone to corrosion from the acids and microbes – known as microbiologically influenced corrosion – in the wastewater passing through them.

According to a paper in the Process Safety and Environmental Protection journal from 2022, ongoing repairs and maintenance to concrete sewer pipes cost Australian taxpayers almost €40 billion ($70 billion) every year. Many of these pipes need to be excavated fully for the work to begin which also causes a huge amount of disruption.

Using waste to carry waste

Researchers at the University of South Australia (UniSA) created the new material by combining sludge with blast-furnace slag, another by-product. The new material was discovered while evaluating the anti-corrosive effectiveness of alkali-activated materials (AAMs), with the full study later published in the Journal of Building Engineering.

Alkali-activated materials – which are also known as geopolymers – are created from a range of materials (usually industrial by-products), known as precursors. These are added to an alkaline medium to produce a cement-like material that can be used as alternative to Portland cement when making concrete.

Why use slag in concrete?

There are many types of cement and different types are used in different concrete applications. Water-heavy environments often use concrete made up with Portland Slag Cement, which is a combination of ground granulated blast furnace slag, Portland cement clinker, gypsum and other additives.

The researchers replaced between 20 and 40 per cent of the slag with alum-based water treatment sludge and found that the resultant concrete was not only 50 per cent stronger than without adding the sludge, but the new material also limited the penetration of sulphur-oxidizing bacteria and slowed acid-induced degradation.

Resource recovery and environmental benefits

UniSA civil engineering PhD candidate Weiwei Duan, whose research is based on the project, believes there is another major benefit: finding a cost-effective and environmental use for water treatment residue.

He told media: “Sludge is usually disposed of in landfill sites, which not only reduces available land for other uses, but also harms the environment, creating CO₂ emissions from transporting the waste.”

Principal supervisor and lead researcher on the project, Professor Yan Zhuge, believes that new material is a vital component of the circular economy.

He told media: “This has the potential to extend the service life of sewage pipes, reduce maintenance costs, and promote the reuse of water treatment byproducts, thus contributing to the circular economy.”

He added: “The construction industry is one of the world’s biggest greenhouse gas emitters, so if we can cut down on the need for cement, we will be helping to lower carbon emissions.”

Building blocks of future research

Prior to the study being published, Weiwei became the first UniSA student to win Australian Water Association’s Student Water Prize in 60 years, for his research: Utilising Alum-Based Water Treatment Residue in Producing Highly Durable Alkaline-Activated Material.