Wessex Water was looking to validate a monitoring platform to help characterise wastewater steam influent. By validating readings, the UK water utility was able to lower organic loading and maximise aeration efficiency. By Tom Williams.

UK water utility Wessex Water serves 2.8 million customers with water and wastewater services across the south west of England.

One of its major wastewater treatment plant (WWTP) manages a combined influent wastewater flow from municipal and industrial clients. The combination and variation of municipal and high strength industrial wastewater flows makes it difficult to maximise aeration efficiency with all biologically activated flooded filter (BAFF) cells being operated to meet peak loading events.

Annual energy use on site is in the region of £500,000. These costs are primarily comprised of aeration energy required for the three treatment streams and ultraviolet (UV) disinfection.

A target of a 10 – 20 per cent energy savings provides a potential for £50,000 - 100,000 in savings per annum with improved aeration efficiency.

Wessex Water was looking to validate that a monitoring platform used to characterise wastewater stream influent, known as SENTRY from Island Water Technologies (IWT), to identify key biological imbalance triggers.

By validating the MET readings, this can be used as a surrogate for organic carbon concentrations, with this reading then used to identify periods of time of lower organic loading to the facility and allow operators to maximise aeration efficiency.

The WWTP receives a combination of municipal and industrial wastewater streams. The treatment process combines an Activated Sludge (AS) treatment system with a Brightwater Biological Activated Flooded Filter (BAFF).

With the goal of better managing nutrient requirements, the flow directed to the second AS and BAFF treat the majority of municipal wastewater.

However, they also receive around 15 per cent of the industrial trade flow while a portion of the municipal flow is also directed to the first Vitox AS plant. All flows leaving the site pass through final UV treatment.

The SENTRY monitoring sensor was placed upstream of a Brightwater BAFF unit. This consists of five treatment cells that contain small pea sized plastic beads for biomass growth/retention. The key advantage of these treatment units is that they also incorporate filtration, so do not require settlement and/or settlement tanks.

These treatment cells take themselves offline each day to go into a backwash to remove captured solids.

There were four main project objectives:

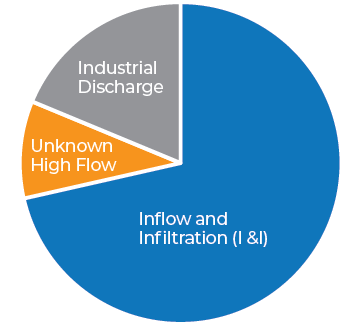

During a three-month period the SENTRY platform identified 21 imbalance events for biological activity. More than 70 per cent of events were triggered by high precipitation and resultant inflow and infiltration.

This is typically represented by a drop in microbial activity and a more dilute wastewater stream entering the plant.

Two events were triggered by unknown cause but arrived with high flow to the facility and four events were triggered by unknown events and no significant change in flow. These four events were presumed to have been triggered by industrial trade discharge into the collection system.

Sensors installed upstream of the Biologically Aerated Flooded Filter.

The platform was set to record a reading every minute with 1,440 readings in a 24-hour period. The MET readings are displayed on an online dashboard with a signal also sent to the on-site supervisory control and data acquisition (SCADA) to integrate with other data being collected at the facility.

Correlation to on-site manual biochemical oxygen demand (BOD) sample analysis (Figure 3 above) and in-line chemical oxygen demand (COD) analysis was carried out.

Data was collected from the SENTRY platform over a three-month period. The bio-electrode sensor platform required only very minor maintenance over this period and generated reliable and robust data very limited signal drift.

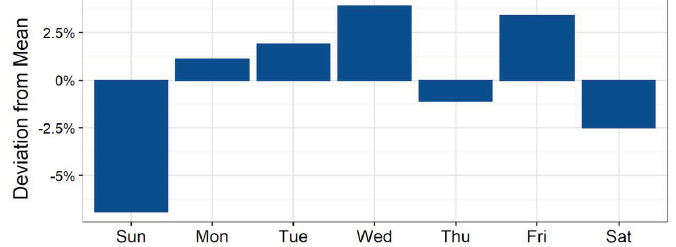

Daily variation of MET. Lower MET on Saturday and in particular on Sunday. Higher activity on Wednesday and Friday.

This historical data set was statistically analysed using a signal decomposition with key repeating trends identified. The weekly pattern of MET at this site shows a wider range compared to typical municipal sites, indicating the impact industrial discharge has on the facility.

Highest loading to the system occurs late evening between 8-10 pm. MET shows a decreasing trend from midnight, with the lowest organic loading happening early afternoons between 12-3 pm.

The duration of lowest organic loading is larger on Sunday and Monday (10am-3pm), while on Wednesday and Friday larger organic loads are observed.

Design information of the BAFF units combined with current and projected wastewater flowrates and strength should be considered before decreasing the quantity of BAFF units active at any time point.

IWT believes that the SENTRY data combined with flow information can be used to pinpoint the historical time periods where the lowest periods of organic loading are coming into the system. These identified periods could be the starting point of efforts to decrease the number of functional BAFF units at any time.

Daily change in organic loading to the facility resulted in clear daily response in MET readings that were inversely correlated to dissolved oxygen concentrations. Low MET periods (high DO) were selected as key periods for process optimisation.

The historical trending from the SENTRY platform showed a consistent period of the day a lower MET reading was identified. From the MET readings it the period from 12:00pm to 3:00pm was identified as being the low-period of microbial activity. By overlaying this data with on-site dissolved oxygen readings from the AS plant, it clearly showed high dissolved oxygen readings that correlate to low periods of MET activity. These readings indicate periods of the day where the facility is being over aerated.

“This process optimisation strategy allows for maximal aeration efficiency while allowing for a reduction in operating costs for the plant.”

Based on these readings Wessex Water will divert more loading during the low organic loading periods from the BAFF reactor to the AS treatment system. This process optimisation strategy allows for maximal aeration efficiency while allowing for a reduction in operating costs for the plant.

Annual energy use on site is in the region of £500,000. These costs are primarily comprised of aeration energy required for the three treatment streams and UV disinfection.

A target of a 10 – 20 per cent energy savings provides a potential for savings in the region of £100,000 - 50,000 per annum with improved aeration efficiency.

Based on the MET readings Wessex Water plans to divert more loading during the low organic loading periods from the BAFF reactor to the ASP.

This flow re-direction will allow operators to minimise aeration requirements for the BAFF system (turning off blowers during low loading periods) and saving energy.

The value of this strategy will result in a saving of £100,000 - 50,000 per annum with key savings in energy consumption as well as blower maintenance and cleaning.

CEO

Enebio