Switching from seawater to rainwater

A “dual mode” desalination plant completed testing and commissioning in Singapore despite “inevitable” Covid-related challenges.

The Keppel Marina East Desalination Plant (KMEDP) is said to be a world first – it can treat either seawater or freshwater from the Marina Reservoir, depending on the conditions.

KMEDP commenced operations at the end of June and was built under a Build, Own and Operate (DBOO) arrangement with National Water Agency, PUB.

Capable of producing 137,000 m3/day of drinking water the plant will be operated by Marina East Water, a wholly-owned subsidiary of Keppel Infrastructure.

A complicated set up

Dr Graeme Pearce, principal at Membrane Consultancy Associates, said the concept of “variable salinity” desalination exists, citing Thames Water’s Beckton desalination plant in London and the Tampa Bay Seawater desalination plant.

However, this is the first example of a plant that can deliberately switch water sources, as opposed to a change in feedwater that occurs naturally, for example depending on the tide.

"While the dual intake system appears simple on the surface, it’s a complicated set up."

Speaking to Aquatech Online, he said: “While the dual intake system appears simple on the surface, it’s a complicated set up with consequences impacting the energy recovery, pumps and controls.”

This has to do with the total suspended solids (TDS) of seawater being in the range of 40,000 mg/L, compared to lagoon water in the range of 2,000 mg/L.

“This means the plant has been designed with two completely different operation modes,” Pearce added. “Ideally, it will have been designed with two sets of membranes specifically suited to the changing feedwater.”

Energy efficient engineering design

Featuring dual intakes, in dry weather KMEDP will treat pumped seawater but in wet weather can switch to treat rainwater from to produce potable water, using less energy.

Keppel Infrastructure’s appointed engineer, Aecom, said this enables a more energy efficient process compared to a typical desalination plant.

The engineering design includes raw water intake from the sea and reservoir to a dual flow chamber, through pre-treatment using flocculation and dissolved air flotation, then ultrafiltration; a two-pass reverse osmosis system; and post-treatment using ultraviolet disinfection.

In addition to using dual water source, KMEDP also implemented other features for energy optimisation, including direct coupling and permeate split.

Technology partner, Pentair, which provided ultrafiltration membranes (UF) to the project, said KMEDP is also the first large-scale desalination plant in Singapore to use the Direct-Coupling UF-RO (reverse osmosis) approach.

This is where the filtrate from the UF pre-treatment is fed directly to the downstream RO process, eliminating the need for a RO break tank and a pumping stage, resulting in “significant cost, space and energy savings”.

For the seawater pre-treatment, Dutch contractor Nijhuis Industries provided eight high rate dissolved air flotation (DAF) units for the removal of solids.

With a total plant recovery rate of 98 per cent, Nijhuis said the i-DAF units have “plate packs that make particles/flocks float to the surface with the injection of air”. According to the company, this helps to reduce footprint requirements by 30 to 60 per cent.

An unconventional water treatment plant

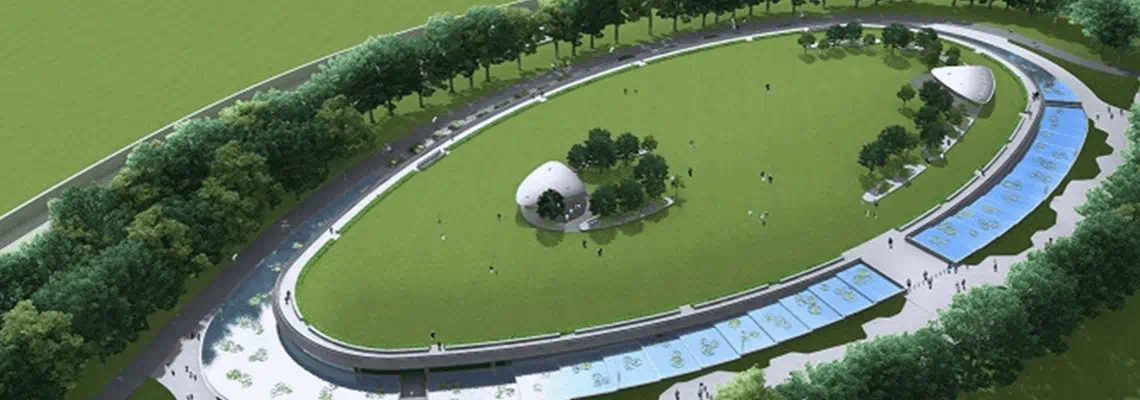

KMEDP was recognised by PUB for a sleek design that seamlessly integrates with the surrounding greenery and breaks away from “conventional water treatment plants”.

Environmentally friendly elements have been incorporated into the plant, including rainwater harvesting ponds and stormwater management systems.

“Multiple land uses” are achieved by situating treatment facilities underground, viewable via a private viewing gallery.

This frees up nearly 20,000 square metres of open green rooftop space for community activity and recreation, Keppel Infrastructure said.

Ng Joo Hee, chief executive of PUB, said the new project could become as iconic as the Marina Barrage.

He said: “The plant’s completion is also eagerly awaited because it is such a special facility: a dual-purpose desalination plant in the middle of our city, integrated with parkland, accessible to the public, and a beautiful piece of architecture.”

Dr On Tiong guan, CEO of Keppel Infrastructure, said: “Completing the final lap of testing and commissioning during the Covid-19 pandemic brought about some inevitable challenges, due to the reduced manpower.

“The commencement of operations is testament to Keppel’s Can-Do spirit and resilience, as we worked closely with PUB and our contractors to overcome these challenges and deliver a successful project.”