Triple carbon reduction: Anglian Water utilises MABR to help reduce wastewater treatment greenhouse emissions

Anglian Water is collaborting with OxyMem™ and Cranfield University to trial an approach to treating wastewater that will reduce greenhouse emissions.

Reducing carbon emissions in wastewater treatment

UK water utility Anglian Water is collaborating with OxyMem™ and Cranfield University to build a demonstration plant to trial a novel approach to treating wastewater that will reduce the amount of greenhouse emissions compared to current processes.

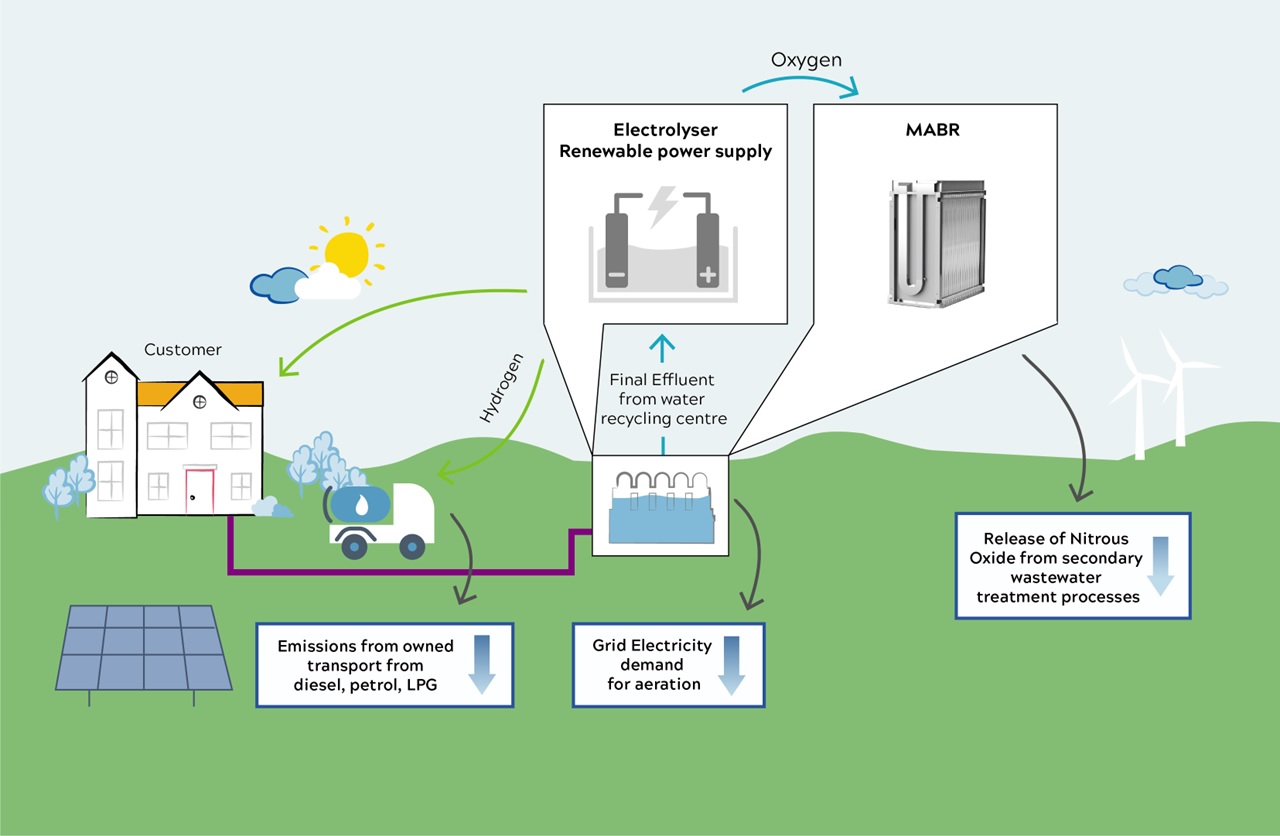

By coupling an electrolyser and MABR (Membrane Aerated Biofilm Reactor), Anglian Water aims to achieve a ‘triple carbon reduction’, in line with the aims of the Water UK Net Zero 2030 routemap, while producing green hydrogen as a renewable energy source.

The plant will be located at Anglian Water’s Cambridge Water Recycling Centre in Milton.

Why is there a need to reduce carbon emissions in wastewater treatment?

The water sector in the UK accounts for almost a third of all greenhouse gas emissions, primarily through waste and industrial processes. The sector has pledged to achieve net zero emissions by 2030 in England and Wales, with Scotland to follow in 2040 and Northern Ireland in 2050.

Generating oxygen as a resource for MABR

The pilot will pass potable water through an electrolyser powered by renewable energy from the site, derived from combined heat and power assets on site, using biogas.

Speaking to Aquatech Online, Giulia Pizzagalli, Innovation Projects Manager, leading the project for Anglian Water, said: “This will split the water into oxygen and hydrogen - approximately 730 kg/d and 90 kg/d, respectively.”

The oxygen will be used as a resource within the MABR, “to enhance the treatment process and target reduction of both energy consumption and nitrous oxide process emissions,” added Giulia.

“Unlike conventional treatment, which uses bubbles to deliver the air necessary for treatment, MABR is a membrane system, where air is supplied to the attached biomass through the bore of the membrane, making it more efficient.

“Our hypothesis is that by gradually adding oxygen to the air delivered via the membrane, the process will have a higher oxygen transfer efficiency to the biomass and thus reduce the energy needed to supply air and stabilise the process to reduce nitrous oxide production.”

The plant design that includes OxyMem™ MABR make it an ideal choice for such a project.

“The plant design that includes OxyMem™ MABR showcases an advanced, intense biological wastewater treatment solution which offers a wealth of benefits,” John McConomy, commercial director at OxyMem told Aquatech Online.

“The plant's compact design with shallow water depth and ease of operation make it a practical and sustainable solution for wastewater treatment needs, saving on extensive civils, concrete works and ground excavation.

The demonstration plant is being runon a small scale for six months, with the trial set to start in May or June, and finish on December 24, 2024. A future full-scale system will use treated effluent from wastewater.

Producing green hydrogen, eliminate harmful gases and saving energy

The project aims to achieve three main carbon-related benefits:

Green hydrogen: Green hydrogen is produced at the electrolyser. The pilot will assess how hydrogen produced in a full-scale system might be utilised. However, during the pilot:

“the hydrogen will be compressed and stored, to be then collected and sold by partner company Element 2, who are working towards building a hydrogen refuelling network in our region and beyond. The initial market for launching this initiative will likely include buses and hydrogen demonstration vehicles (e.g., trucks, refuse collection vehicles and vans),” added Pizzagalli

Eliminate greenhouse gases: Nitrous oxide (N20) is 300 times worse for the atmosphere than carbon dioxide. One of the reasons for using MABR in the project is to demonstrate its potential to eliminate the production of this harmful gas as a by-product of wastewater treatment.

“Eyes are opening wide to N2O emissions within the sector and significant effort is being put into learning more on both production and reduction of this greenhouse gas, within wastewater treatment,” added John McConomy.

“Understanding these intricacies will enable engineers and owners to pinpoint key areas for intervention and develop targeted solutions. Initial results from MABR trials elsewhere suggest that a bubble-less MABR solution could help address harmful N2O emissions in aerobic wastewater treatment.”

Reducing energy consumption: Anglian Water estimates that this approach to treatment of wastewater in its sewage plant will consume 85% less energy than its current processes.

OxyMem™ John McConomy agrees: “Treating wastewater is a crucial process that consumes a significant amount of energy globally. With developed nations like the UK dedicating around 3% of their total energy usage to this task, and with wastewater aeration typically making up <60% of this figure, an MABR solution that may save 4-10 times on energy usage stands to help us greatly on our road towards Net Zero.

“Each of our modules draw little more energy than a conventional lightbulb so energy will be a fraction of that used on conventional systems,” he added.

Assessing the business case for scaling up

A team at Cranfield University, in collaboration with OxyMem™ and Jacobs, will analyse data as it is produced to identify the best way to balance both the reduction in nitrous oxide emissions and reduction in energy use, while ensuring the treatment of wastewater operates at maximum efficiency.

Cranfield University will also be working to identify alternative approaches to cost-effective and more sustainable pre-treatment options for the final effluent electrolyser water feed.

Brunel University will carry out a lifecycle assessment of resource recovery and hydrogen implementation pathways at the plant. This will determine whether higher energy efficiency and lower emissions can both be achieved and assess what the findings mean for future plants.

The University of East Anglia is assessing how customers and the local community feel about the installation of hydrogen production facilities at wastewater treatment plants. The insights will be used to inform how the sector approaches future customer engagement around sustainability issues.

Meanwhile, Element Energy will assess the system as a whole, in particular, potential end users for the both the amount of hydrogen produced at demonstration plant and larger customers that would be willing to take the hydrogen that will be produced by full-scale plants.

John McConomy believes the project could have a huge impact on wastewater treatment in the next few years: “Without doubt, insights and data collected from the Triple Carbon Reduction initiative may revolutionise how wastewater treatment plants are designed going forward, reducing environmental impact and paving the way for a greener future in wastewater management.”