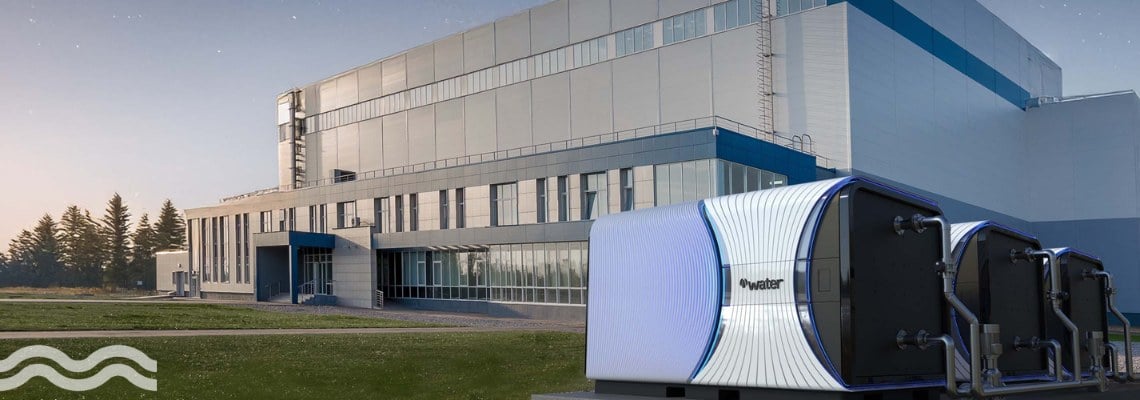

US-based advanced water treatment solutions company VVater has been named as one of Time Magazine’s best climate inventions (2025) for its electro-hydro treatment system. This completes a trio of prestigious awards, following the CES Best of Innovation Award and the World Future Award – the first time any company has won all three in the same year.

Aquatech Online spoke to the VVater’s CEO and chairman, Kevin Gast, to learn more about the company’s award-winning innovations, how its core processes work, and to find out why physics may be a better approach to water treatment than chemistry.

VVater’s treatment system is built on two innovations: the Farady Reactor and the ALTEP (advanced low-tension electroporation process) system. But where did the inspiration come from, and how long did it take to bring the company’s ideas to market?

“The inspiration came from a simple but powerful question: What if we could treat water using physics instead of chemistry?” explains Gast.

“VVater’s engineers drew from advanced electrodynamics, biomedical research on electroporation, and plasma physics to create a process that mimics natural oxidation and reduction but under complete human control and prediction.”

Originally incubated in a larger conglomerate. VVater became its own entity in 2023. However, development began much earlier.

“Development of the Farady Reactor and the ALTEP system began nearly a decade ago, with the first lab-scale prototype built in 2017, pilot testing between 2018 and 2019, and commercial deployment starting in 2019,” adds Gast.

Today, the ALTEP system is used in industrial reuse, municipal treatment, and direct potable reuse (DPR), while the company has also developed other water treatment technologies, such as Advanced Dissolved Flotation Devices (ADAF), and both micro and nano bubble nozzling technologies.

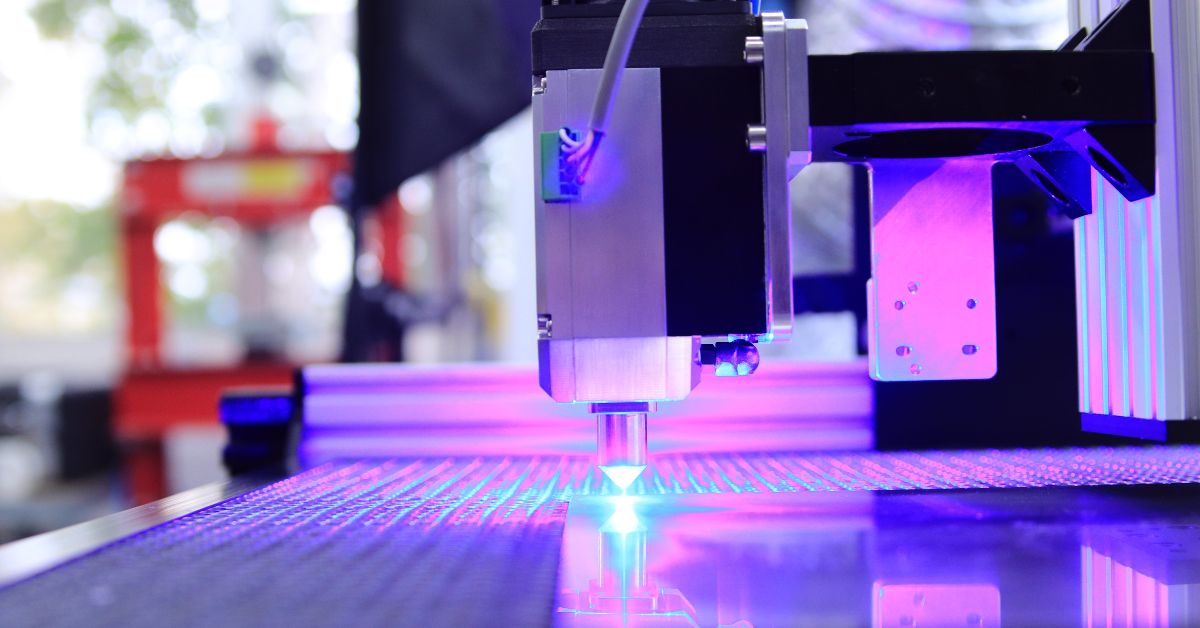

Sitting at the heart of the company’s technology is the Farady Reactor, a next-generation electro-hydro treatment system.

Gast explains how it works: “It uses controlled electric fields and harmonic energy to purify water without chemicals, filters, or membranes. Instead of forcing water through barriers like reverse osmosis or adding oxidants, the Farady Reactor uses carefully tuned electrical waveforms to activate natural reactions already present in water, splitting molecules, neutralising contaminants, and sterilising microbes, all in a single pass.”

Deployed as a compact, modular system, the Farady Reactor can be used to treat a wide range of source waters, from small community supplies to industrial or municipal flows.

Within the Farady Reactor, VVater’s Advanced Low-Tension Electroporation Process (ALTEP) provides proprietary field-control. But what does this mean?

“Traditional electroporation uses high-voltage electrical pulses to disrupt cell membranes in biology labs,” begins Gast. “VVater re-engineered that concept for water treatment using a low-voltage alternating current, creating oscillating microelectric fields that destabilise microbes, breaking molecular bonds, in real time.”

With no moving parts, no filter media, and no membranes, the system resembles a stainless-steel reactor and is delivered as a plug-and-play module that integrates directly into existing treatment systems.

One of the biggest challenges facing water companies is how to effectively ‘treat’ contaminants and pollutants, such as pharmaceuticals and per- and polyfluoroalkyl (PFAS) substances, whether that involves simply capturing them or destroying them entirely.

Gast explains how the reactor breaks down PFAS: “Inside the Farady Reactor, alternating electrical fields in different chambers and cassettes create two reactions: oxidation and reduction.

During the oxidative phase, highly reactive oxygen species (like hydroxyl radicals) are generated, which attack organic pollutants such as pharmaceuticals and microplastics.”

He adds: “During the alternating phases, hydrated electrons and atomic hydrogen break apart ultra-strong chemical bonds, including the carbon-fluorine bonds found in PFAS, effectively defluorinating these forever chemicals into harmless fluoride ions and smaller carbon fragments.”

According to the company’s website, the system generates no waste, so what happens to the broken-down contaminants?

“In conventional systems, contaminants are concentrated and disposed of elsewhere. In VVater’s process, contaminants are chemically converted, not just moved, depending on feedstock water quality,” Gast explains. “For example, in sewerage wastewater, VVater averages roughly two per cent of waste, meaning above 98 per cent recovery.”

He adds: “Organic compounds are oxidised into simple gases such as carbon dioxide and nitrogen, or reduced into stable mineral salts. Some heavy metals are electro-precipitated and easily collected in solid form for safe disposal or recycling.”

Reverse osmosis (RO) works by forcing water through membranes at high pressure, which consumes large amounts of energy and produces concentrated brine waste.

The Farady Reactor operates with no pressure and no membranes, relying instead on low-voltage electrical energy, which uses roughly one-tenth of the energy used by typical RO systems.

“Efficiency has been confirmed through controlled lab studies and field-scale validation using industry-standard ASTM and EPA analytical methods, demonstrating equivalent or superior contaminant removal with drastically lower energy input and zero waste byproduct,” explains Gast.

So far, VVater has treated over 4.3 billion gallons, in addition to more than 8000-plus lab tests carried out across the globe.

VVater is first and foremost an engineering company that is to a degree technological agnostic and it’s systems can be used in a wide variety of scenarios, as Gast explains:

“The core physics and chemistry of the Farady Reactors are similar in different applications. At residential scale, the Shield™ system uses smaller Farady Reactors for point-of-entry treatment, with an AC/DC water softening module and purifying household water without filters or salt. At industrial and municipal scales, the same technology scales linearly by adding multiple reactors in sequence, maintaining the same energy efficiency and treatment profile.”

There are, however, some limitations: “We realise that our Advanced Oxidation Process or Advanced Reduction Process technologies will not work everywhere. As such, our objective is to solve the customer’s problem even if that means using conventional or traditional technologies adjacent to ours.”

It is not a desalination technology, and there are limitations around solids with large particulate sizes. To overcome such challenges, the Farady Reactors can be used in a treatment train with other technologies to handle a wide variety of influent conditions, from secondary treatment onwards to industrial applications treating water to an exceptionally high quality.

However, it is essentially the same design that powers the home-based Shield system that is used in the ALPHA™ Mobile Water Treatment System, which is a trailer-based unit capable of treating up to 100,000 gallons per day for disaster relief, remote sites, or for temporary industrial needs.

Gast sees the electrification of water treatment as having a very bright future.

“The technology currently outperforms a fast array of solutions in the market however our technology is still in its infancy stages and our objective is to further refine, understand and micronize our technology,” he says.

“We realise there are infinite possibilities from residential markets and home pool systems to military applications. We have been systematically approaching specific verticals and challenges where we can make the most impact and solve water shortage problems.”

One of those challenges will be to tackle the complex chemistry of destroying PFAS in commercial settings. Another goal is to further develop the company’s Redstar AI system that will use “vast amounts of in-line sensors” to detect and understand fluctuations with influent so that it effect real-time changes/tweaks to a treatment system to ensure a constant quality output.