It would almost be impossible not to have heard of Per- and polyfluoroalkyl substances (PFAS). From being relatively unknown in the wider world to becoming a topic of everyday conversation, from supermarkets to business conferences, and from gyms to cabinet meetings. These days, everyone has heard of PFAS.

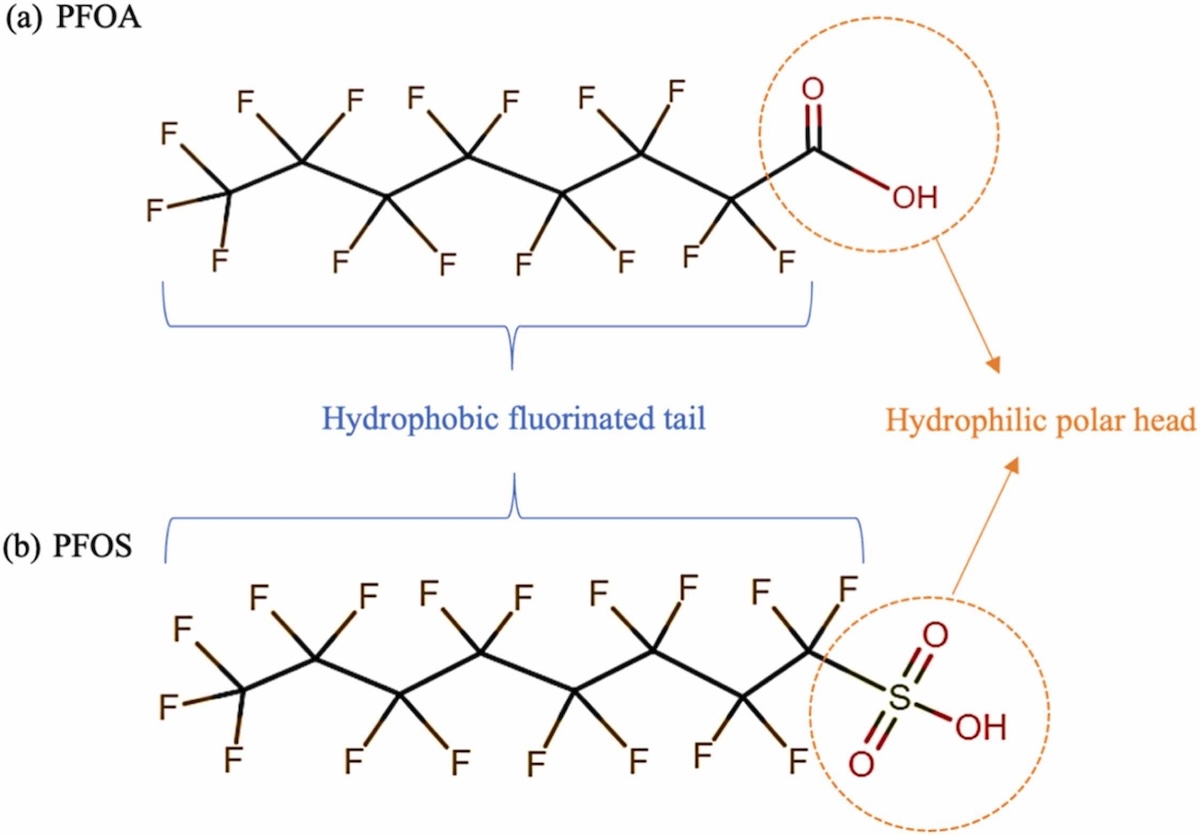

Commonly known as 'forever chemicals', PFAS is a collective term for up to 15,000 synthetic substances found in various everyday products, such as firefighting foam, non-stick cookware, and water-repellent fabrics.

Their use over many decades has resulted in widespread contamination of both the land and water sources.

Despite not creating or using PFAS, the water industry is at the forefront of the fight to detect, remove and destroy these substances. EurEau, the European federation of national associations of water services, stated in an open letter to the European Commission in 2024: “PFAS pollution isn’t a water industry problem, but it is a problem for the water industry…”

Left alone in the wild, they are highly persistent and, in some cases, almost impossible to break down. This allows them to accumulate in ecosystems, potentially disrupting aquatic life and food chains.

Contamination of land and water spreads to the food chain and drinking water, with potentially serious consequences. For example, PFAS are listed in the Stockholm Convention on Persistent Organic Pollutants and come with a series of health warnings. These include:

Perfluorohexane sulfonic acid (PFHxS), its salts and PFHxS‐related compounds: the convention warns that exposure in humans could have an influence on the nervous system, brain development, endocrine system and thyroid hormone. Other PFAS listed in the convention are:

Many countries and cross-border organisations have begun the long ‘clean-up’ process. This involves tackling both historical pollution and updating guidance and regulations, in a bid to significantly reduce the use of PFAS chemicals wherever possible.

Even countries like France and Denmark, which are introducing outright bans, carry exemptions and compliance extensions, such is the nature of PFAS use in vital safety equipment, such as in fire-resistant materials and firefighting foam.

The European Union has voted to adopt a Water Resilience strategy that calls for the phasing out of all PFAS chemicals, ‘wherever safe alternatives exist’. Water sustainability and resilience will now be the cornerstone of all EU policies, ensuring every future policy is assessed for its impact on water quality, quantity and accessibility, including tackling pollutants such as PFAS.

Meanwhile, the European Chemicals Agency has put forward a proposal that would limit the use of PFAS in industrial and manufacturing processes. By restricting their use, the Agency aims to mitigate the risks associated with PFAS contamination. However, progress is slow, and a resolution isn’t expected until 2026.

The French National Assembly passed a law that bans the use of PFAS in many products from 2026, making it the second European country, after Denmark, to announce such a plan. The law also puts the cost of cleaning and destroying PFAS on the polluter rather than water utilities. The ban covers a wide range of products, including cosmetics and waterproof clothing, but excludes cookware and protective clothing worn by firefighters. There are two stages: the first in 2026, the second in 2030. It covers the manufacture, import, export, and marketing of products containing PFAS.

Denmark’s ban comes into force in 2026 and covers the manufacturing of paper and cardboard food packaging, with a ban on the sale and import of consumer clothing, footwear, and waterproof materials. Denmark is also improving monitoring and providing funding for the water and soil clean-up process.

Australia has designated PFOS, PFOA, and PFHxS (including their salts, isomers, and precursors) as Schedule 7, the highest level of concern, under its Industrial Chemicals Environmental Management Standard (IChEMS). This prohibits the intentional import, manufacture and use of these PFAS in chemicals, mixtures and articles.

The government has also issued its Commonwealth Environmental Management Guidance policy document to assist government agencies in assessing and managing PFOS and PFOA contamination. It provides a nationally consistent framework for diagnosis and action on environmental contamination.

The US has created a role within its Environmental Protection Agency dedicated to PFAS remediation. Heading up the effort is Lee Zeldin, who was a founding member of the PFAS Congressional Taskforce. Recent measures include the creation of effluent limitations guidelines (ELGs) for certain PFAS to stop these forever chemicals from entering drinking water systems, and initiatives to engage with Congress and industry to establish a clear liability framework that ensures the polluter pays and passive receivers are protected.

PFAS remediation measures are focused on three main areas: Strengthening the science, fulfilling statutory obligations and enhancing communication; and building partnerships between key stakeholders, including states, to help develop tools and working practices to support monitoring and clean-up processes.

However, the EPA has extended the date for water systems to comply with regulations outlining the removal of PFAS from drinking water, and is reconsidering how it regulates a subset of the forever chemicals. Compliance deadlines for PFOA and PFOS now have a deadline set for 2031.

Here we take a look at seven companies that are tackling PFAS pollution, as well as two universities working to advance new destruction technologies.

Swiss-based company Oxyle offers modular solutions, which destroy PFAS and produce treated water that is even cleaner than bottled water. The company has recently launched Oxyle’s PFAS Solutions, which can be adapted to suit any user's needs.

Oxyle's original solution used a catalyst that is activated by turbulence in water to break down and mineralise broad-spectrum PFAS (from ultra-short to long-chain) into harmless by-products, such as fluoride ions, sulfate ions, and carbon dioxide. However, this technology has now been retired and, responding to customer demand, replaced by PFAS Solutions. These are modular systems designed to eliminate the most challenging short and ultra-short-chain PFAS. They comprise several proprietary technologies, including:

These modular systems can be tailored to meet each client’s unique demands.

Axine's solution uses electrochemical oxidation technology to remove PFAS. The company’s electraCLEAR treatment involves immersing conductive electrodes into a flowing process stream. By applying an electrical potential (voltage), electrons travel from the anode (negative electrode) to the cathode (positive electrode). The selection of electrode materials and applied current largely determines the process reactivity and chemical reaction pathways for treatment.

For challenging compounds like PFAS, electrons are directly transferred at the anode's surface, initiating chemical oxidation. The oxidised contaminant can then react with hydroxyl radicals, ozone, and various chemical radicals/oxidants generated in the process to enable degradation.

Continuous water circulation, with adjustments to applied energy, ensures the desired treatment level is achieved.

electraCLEAR's key innovation is its ability to utilise multiple different catalysts and electrode materials simultaneously within a single reactor. This maximises treatment performance, energy efficiency, and electrode lifespan.

Users are supported by a suite of online instrumentation that uses Axine's proprietary machine-learning/artificial intelligence (ML/AI) algorithm. This offers real-time monitoring and optimisation of system performance and operating cost.

The system, which can be deployed in a container, destroys contaminants down to their elemental building blocks, such as dissolved carbon dioxide, nitrogen gas, hydrogen gas, oxygen gas, and some dissolved mineral salts. This leaves no solid or liquid waste products leftover, which allows the treated wastewater to be directly discharged.

An agreement between US-based water and wastewater treatment company, Ovivo, and Australian company Evocra offers an on-site solution that isolates and destroys PFAS using a combination of ozone foam fractionation processes and electrochemical oxidation technology.

Katie Henderson, product group manager for Ovivo's PFAS Solutions product group, told Aquatech Online: “Adding ozone foam fractionation to Ovivo's toolbox of PFAS Solutions enables cost-effective PFAS removal and destruction for municipalities and industry as we all seek affordable ways to comply with the new requirements imposed by regulators.”

During early tests on multiple landfill leachates, the system achieved 99.9 per cent destruction of total detectable PFAS using electrochemical oxidation technology on the concentrated PFAS waste generated by Evocra’s ozone foam process.

US-based Gradiant’s ForeverGone is an all-in-one containerised solution that removes and destroys PFAS chemicals. Containers can be used in series to increase scale.

Both municipal and industrial water sources can be treated onsite using two technologies. First, micro-foam fractionation injects billions of microbubbles into ‘contaminated’ water to separate and concentrate PFAS into a micro-foamate, which is optimised for immediate destruction. This process does not generate waste or use harsh chemicals.

Once the concentrated micro-foamate has been created, the Destruction Engine uses proprietary electrodes to transform PFAS into harmless byproducts through a process of electro-oxidation.

The technology can destroy long, medium and short-chain compounds with a destruction rate greater than 99 per cent.

Aquagga’s containerised solutions use hydrothermal alkaline treatment (HALT) technology to break down and deflourinate PFAS into virtually non-detectable levels that can be safely added back to a wastewater stream.

Containers come in three sizes: Colt, which is able to process 1 gallon per hour (g/h); Steed (5 to 10 g/h); and Stampede (60 g/h). These can either be integrated into existing wastewater systems or deployed remotely to treat stored wastewater sources.

Instruments within the containers provide remote monitoring of flow, pressure and pH and offer an optional service for periodic automated sampling of the water passing through the system.

HALT technology effectively closes the loop on PFAS destruction, ensuring that PFAS is destroyed onsite. It does this by first concentrating the volume of PFAS-containing wastewater by a factor of 1,000 or more. This highly concentrated PFAS solution is passed through the continuous flow HALT system.

HALT processing destroys and defluorinates up to 99.99 per cent of the PFAS in this stream. The persistent carbon-fluorine bonds are broken, significantly reducing PFAS concentrations and eliminating a substantial quantity of PFAS on a mass basis.

This leaves a salty liquid effluent with trace residual PFAS concentrations often lower than in the original wastewater feed. According to the company, destruction of PFAS via HALT has been evaluated and proven using multiple analytical techniques.

The HALT effluent is then blended with the original, untreated wastewater stream.

Puraffinity’s Puratech G400 is an adsorbent material consisting of hard, white granules approximately 0.5mm in width. The system is designed to be a fully customisable plug-in solution that can fit into an existing water treatment system, saving time and costs. In trials, it has been proven to capture a large variety of different PFAS chemicals and demonstrated seven times more capacity to remove PFAS when compared to petroleum-derived ion exchange resin solutions, according to the company.

Vincent Caillaud, CEO of Puraffinity, told Aquatech Online: “Our technology’s enhanced efficiency, extended lifespan, lower installation costs, and reduced need for frequent replacements help to minimise long-term resource use and waste. G400’s ability to selectively target a broad range of PFAS compounds, including both long- and short-chain variants in complex water conditions, ensures reliable performance across varied environmental challenges.”

It achieves this using shorter contact times with contaminated materials and with a smaller footprint than similar products.

US-based company AqueoUS Vets’ FoamPro system employs an innovative vacuum process that, according to its creators, improves mass transfer efficiency and reduces energy consumption compared to conventional foam fractionation technologies.

The system is housed in a vertical unit that is taller than it is wide, which has the benefit of requiring only a small on-site footprint and which actively aids the foam process.

CEO Dr Mirka Wilderer, told Aquatech Online: “FoamPro is a foam fractionation system designed with simplicity, energy efficiency, and performance. It uses a vacuum air lift instead of traditional high-pressure air systems to create foamate. Rather than pushing air through water with compressors, FoamPro gently lifts water and air together using a vacuum. This creates ideal bubble formation conditions for removing PFAS without the need for extra pumps, fine-bubble diffusers, or chemical defoamers. It’s a cleaner way to separate PFAS from water, with a strong focus on operational ease and long-term reliability.”

And while the system has been in use in more than 100 non-PFAS treatment applications for some time, it has recently been validated by the US Environmental Protection Agency (EPA) for hard-to-treat wastewater streams.

The system can be delivered and installed in modules, offering a ‘plug and play’ system to meet client needs; module flow ranges from 0.5 gallons per minute (g/m) to 100 g/m.

Engineers at the University of British Columbia (UBC) have developed a high-speed, all-in-one, catch and destroy solution for treating PFAS that has the potential to work with low levels of UV light.

The two-step solution uses adsorption to trap PFAS chemicals on an activated carbon filter containing a special catalyst. The catalyst, which can be produced from forest or farm waste, breaks 90 per cent of PFAS chemicals down into harmless components in as little as three hours.

Dr Johan Foster, lead researcher and associate professor of chemical and biological engineering at UBC, told Aquatech Online: “The adsorption material we use degrades the PFAS into smaller molecules that are non-toxic and environmentally benign, such as fluorine. Since the material is made of carbon with iron oxides, it can be buried or disposed of at the end of its working life.”

Foster also mentioned that the process is fairly quick, depending on how much water is being treated, adding: “We can put huge volumes of water through this catalyst, and it will adsorb the PFAS and destroy it in a quick two-step process.

Meanwhile, researchers from the University of Illinois-Champaign, USA, have created a single-step device for capturing and destroying diverse PFAS chemicals that uses redox electrodialysis and electrosorption.

The method is capable of capturing, concentrating, and destroying diverse PFAS chemicals in water using a single process, including common ultra-short-chain PFAS.

It works by desalinating PFAS-contaminated water to remove ultra-short-chain molecules; at the same time, carbon electrodes remove the remaining short- and long-chain molecules.

This process concentrates the PFAS, making them easier to destroy through the electrochemical oxidation process inherent in redox electrodialysis. The process converts the PFAS to fluoride ions, a key step towards eliminating these persistent contaminants from the environment.