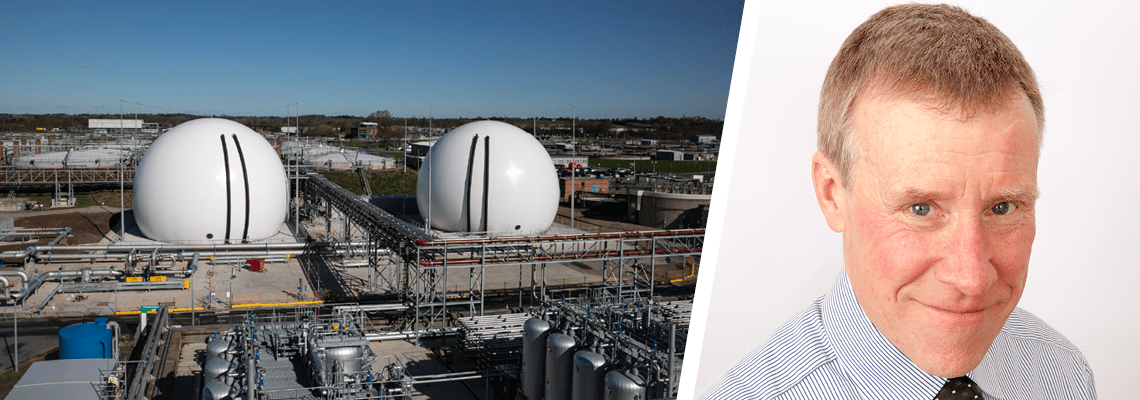

Mick Dawson: Why taking sludge digital makes sense

Mick Dawson

Mick Dawson

Dealing with increasingly difficult sludge

By digitally mapping the sludge pipe network, water utilities can make pumping operations more efficient on the road to meet carbon and energy goals, writes Mick Dawson.

Population growth and legislation restricting disposal to land are directly impact on sludge processing. And with utilities using techniques like thermohydrolysis, it can result in sludges with higher dry solids content.

As a result, existing equipment now has to work harder, moving thicker, more concentrated sludges that are more difficult to pump.

Furthermore, with water companies in England setting out to reach the goal of net zero carbon emission by 2030, more efficient sludge pumping can help them on the journey. However, most utilities have not yet acted to reduce the carbon and financial cost of transportingsludge.

As with any application, accurate selection and sizing of pumps used for the transport of sewage sludge has important cost implications, along with operational risk management considerations.

Under-sizing can mean failure to achieve the required throughput, whilst oversizing leads to excessive capital cost and energy consumption. Utilities can no longer squander energy and emit unnecessary carbon and the cost challenge means they need to get to know their assets and process streams much better.

Understanding sludge rheology

The need for leaner pump systems means more variables need to be taken into account, which can be challenging where the data is not readily available. At the heart of making sludge transport and pumping more efficient is the need to better understand sludge rheology – how it flows.

Variables include pipe size, length, roughness, fittings and elevation as well as the viscosity and temperature of the sludge and the flow rate desired by the operator. To ensure efficient pumping systems, design engineers estimate total pressure losses across the range of variables at a given site. If these estimates are inaccurate this can result in oversized pumps and higher frictional losses, adding considerable capital and operational cost to any system.

The good news is that engineers can now predict sludge rheology and assess and interpret the impact and interaction of these variables through a sophisticated systems losses tool developed by BHR Group. Called SLOT 2.0 and launched in January 2020, the software program developed as part of a research programme originally funded by UK water companies and suppliers.

Fifteen utility and contracting companies in the UK have already trialled sludge management operations with SLOT 2.0 and feedback to date has been very positive.

Indications are that the value of being able to predict and manage sludge network performance at the desktop, before going out on site, will prove massively powerful going into AMP 7 – the regulatory asset management period 2020-2025.

Operating efficiency

The software enables pump system operators to understand where each pump should be operating on its pump and efficiency curves, matching against the particular system pressure curve to find the operating point.

This makes it possible to determine optimum pump-operating points and identify the most effective pumps to use on a given system – selecting the optimal size, type, quantity and configuration, right down to the manufacturer. Potential blockages can also be identified by monitoring the actual versus the predicted pump performance.

The software shows what is actually happening in the network and can be used to generate scenarios in advance of anticipated changes to the system or the sludge rheology. This means it is now possible to specify pumps more precisely than ever before and the capital cost and optimum energy consumption can be calculated well ahead of installation.

Creating ‘Digital Twins’ of the sludge pump network

It is realistic to envision pump system designers using this software to create a ‘Digital Twin’ of the sludge pipe network. Being able to accurately compare pressure and flow in the real network with SLOT’s predictions, it is possible to see, for example, what would happen to pump operation in the event of a struvite blockage; or how the system would respond if a sludge stream was thickened by eight per cent.

Using this system, utilities should be able to make investment decisions based on the most comprehensive assessment possible of both capital and whole-life cost of assets, bringing down the total expenditure required. The possibilities do not end there though.

The long-term outlook heralds greater capacity sludge systems with higher velocity throughput and solids content, which means the need for close attention to the whole performance envelope is only going to grow.

Mick Dawson

Consultancy Director

BHR Group