Fatberg detecting 5G sewer ‘nervous system’ goes down under

When you bang your toe, the human nervous system instantly transmits a signal to tell the brain where to feel pain. Ouch.

Imagine a similar system for sewer pipes that could inform utilities exactly where a crack or potential blockage of fats, oils, greases and wipes – known as fatbergs – is taking place, all in real time.

Well such an idea is being turned into a reality.

British organisation nuron has raised over £2 million in investment, loans and grants and is working to commercialise and scale up a fibre technology that acts like a human nervous system, but for sewers.

Developed in conjunction with Sheffield University, the company believes its solution could disrupt what has historically been a low-tech part of the water cycle network: transporting wastewater from source to treatment.

How it works

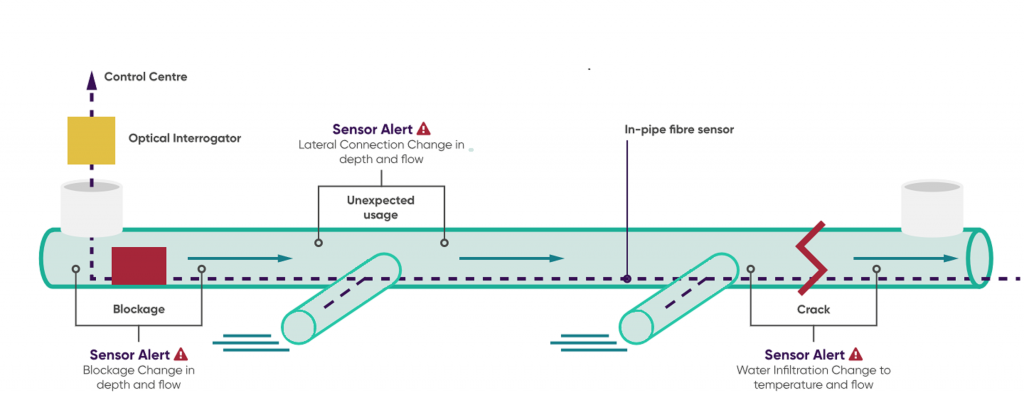

The fibre sensor extends along the bottom of sewer pipes with claims to be able to measure flow, depth, temperature and structural integrity every five metres along the sewer pipe.

“By measuring multiple parameters at the same time, every 5m along a sewer network, it enables potential incidents to be accurately diagnosed, alert, rapidly localised and averted,” the company said.

To differentiate itself from existing sewer sensor technology, the company’s fibre sensing technology is not ‘spot’ but rather offers ‘continuous’ in-pipe monitoring.

Although distributed acoustic sensing technology is not new, currently being used in oil and gas market, the company believes “enhancements” will ensure it works in open flows, rather than pressurised systems.

nuron is hoping its system can serve two purposes: predictive management of sewers but also a way to roll out digital infrastructure by integrating broadband and 5G networks fibre cable networks into the sewer pipes.

Going down under

Northumbrian Water in the UK will be the first utility to adopt nuron’s solution.

A pilot project in a “live operational sewer” will take place for eight months, with installation set for December and initial results in early 2019.

To retrofit old pipes, sewer flow will be stopped before pipe cleaning. A robotic system is then used to pull the containment through the sewer, before installing it backwards, in turn “sticking” it to the sewer floor.

Sally Askew, sewerage project manager at Northumbrian Water said the technology will enable the utility “to understand how to pro-actively monitor the sewer network in real-time” with the aim to “identify issues such as blockages before they affect customers”.

Australia’s largest water and wastewater provider Sydney Water has also signed up as a partner on the Northumbrian trial and will gain access to the data.

According to nuron managing director Claire Fenwick, the Australian utility is specifically interested in how the fibre sensors can detect hydrogen sulphide, a challenge in the Australian market as result of numerous metal sewer pipes.

"This project, is an opportunity for Sydney Water to gain real time, sewer data to improve its services.”

head service planning and asset strategy at Sydney Water

Paul Higham

Spot the competition

Addressing why the business is focusing on sewer pipes, Fenwick said: “We could have started out on drinking water networks but we chose not to as multiple solutions already exist in this space.

“We found that in wastewater there was virtually nothing, apart from spot monitoring, to measure the operational performance of sewers.”

The managing director added: “It’s a challenging environment. On the clean water side, it’s easier to address from outside of the pipe. Whereas if you want to know what’s happening on a gravity fed sewer system, you need to have in-pipe solutions.”

Nuron’s short-term plans are to keep focused on the UK market, with the “utilities going through a digital transformation”, before looking internationally, she said.

Fighting fatbergs

One of the potential areas where the technology could benefit water utilities is the detection of fatbergs: extreme masses of wet wipes, nappies, fat and oil forming rock-hard concrete blocks in sewer pipes.

Utility Thames Water estimates it spends £1 million per month clearing blockages from sewers in London and the Thames Valley alone.

The utility made headlines after its sewer maintenance team discovered a giant 250 metre long fatberg weighing 130 tonnes – the same as 11 double decker buses.

Using the nuron system, if a blockage occurs then the depth and flow change would be detected and an alert sent to the control centre, according to the company’s schematic (pictured below).

Industry reaction

Wastewater industry consultant and expert Jan Pereboom believes coupling the technology with telecommunications services can help offset the capital investment.

“Using the nuron fibre network for other services like broadband and 5G can substantially reduce investment costs for such networks,” he said.

“This new monitoring system will not make conventional camera inspection redundant, but such systems can be used in more dedicated applications.”

Pereboom said the company’s claims still need to be evaluated in “large-scale and long-term testing but seem more than plentiful and thus justify such large-scale tests”.

Meanwhile, Oliver Grievson, group manager of the Water Industry Process Automation and Control (WIPAC) group, said: “The nuron technology is certainly interesting, with claims to be able to measure both level and flow. However, what I don’t see is how - there doesn't seem to be any "sensor" per se and optical fibre is not going to do it on its own.”

Grievson added: “There is also a big debate over whether you actually need flow in a gravity sewer or actually whether just level is more useful.”

Related content

Share your water technology stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the international water technology industry? The Aquatech website and social media channels are a great platform to showcase your stories!

Please contact our Sr Brand Marketing Manager Annelie Koomen.

Are you an Aquatech exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.

We promise never to send you spam and you can unsubscribe at any time!

.jpg?h=628&iar=0&w=1200)

.jpg?h=628&iar=0&w=1200)