3D printed membrane start-up backed by US computer giant

Start-up Aqua Membranes that uses 3D-printed spacers has been backed by US semiconductor manufacturing company, Micron.

Increasing membrane efficiency

A start-up that uses 3D-printed spacers to increase membrane efficiency has been financially backed by US memory and storage solution manufacturing company, Micron.

While the investment into Aqua Membranes remains undisclosed, the 21 billion dollar revenue a year company Micron said the technology could “increase the efficiency of reverse osmosis filtration” and help the organisation achieve its goal of water reuse.

Micron plans to launch a pilot program using Aqua Membranes’ technology at its Boise site in Idaho. If successful, this program could be expanded to sites around the world, the company said.

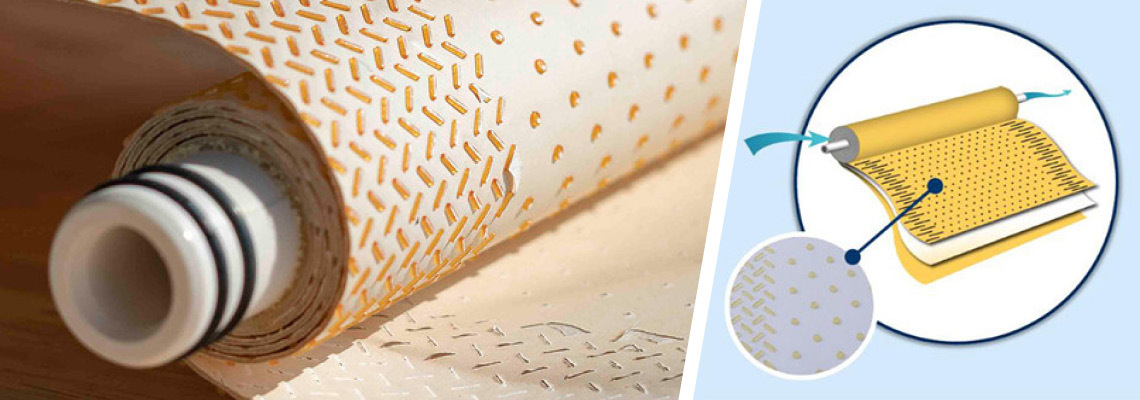

Aqua Membranes creates 3D-printed spacers that it said can increase the efficiency of water filtration. The company’s patented process prints dimensional polymer shapes directly on flat sheet reverse osmosis (RO) membranes to replace conventional feed mesh.

“This is problem solving through innovation.”

Placed inside reverse osmosis systems, the spacers can “optimise flow patterns and turbulence through the membrane element. This optimisation leads to lower energy consumption, reduced system footprint, improved cleaning and potentially longer element life.”

“Aqua Membranes’ reverse osmosis innovation could be an elegant and cost-effective way to improve on equipment already operating in Micron fabs while increasing water reuse,” said Marshall Chase, director of sustainability at Micron. “This is problem-solving through innovation.”

Meeting water reuse goals

Water is an essential ingredient in the manufacturing of semiconductors. A series of cleaning steps are needed to create ultrapure water to ensure process quality.

As semiconductor technologies have become more complex, water demand has grown. As a result, reducing water use is becoming a top priority for many global companies.

Recent news from Taiwan, a global semiconductor powerhouse, has revealed the potential impact of crippling water scarcity on the country’s manufacturing capabilities.

Micron said it is working toward its goals for water reuse and other environmental benchmarks set out in its sustainability report.

“It’s even more important that we don’t wait for the technology to come to us.”

By 2030, the organisation has set the goal to achieve 75 per cent water conservation through reuse, recycling and restoration.

As a result of the investment, Andrew Byrnes, Micron’s director of Venture Capital, said that they could launch a water reuse pilot much faster.

“It’s important we adapt, prove out and scale Aqua Membranes technology for use in our fabs [fabrications], and it’s even more important that we don’t wait for the technology to come to us,” he said.