One answer to more sustainable desalination? Go 400m underwater

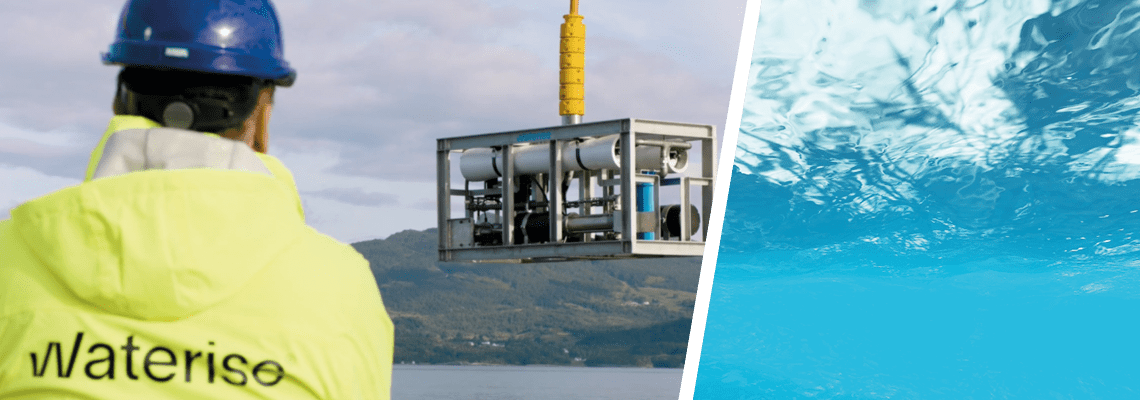

Norwegian start-up Waterise has developed a novel desalination approach to operate 400m underwater on the seabed, claiming huge savings on energy and footprint. Tom Freyberg speaks to the company to find out more.

Natural hydrostatic pressure

A Norwegian start-up believes it has the answer to more sustainable desalination: going deep under the seawater it will be treating.

While traditional desalination plants are typically located near the oceans to filter seawater, technology company Waterise instead wants to take desalination to the bottom of the sea.

The reason? By submerging containerised desalination systems, the company believes it leverages natural hydrostatic “pre-membrane pressure”.

A pilot project in Boknafjorden, Norway, has so far demonstrated a 40 per cent reduction in energy compared to conventional reverse osmosis (RO) technologies. Furthermore, Waterise believes its solution requires 80 per cent less land than land-based plants.

Privately backed by Norwegian shareholders, the company is moving forward on its first commercial installation in Saudi Arabia, the largest desalter globally. Other discussions are underway in Egypt, the Canary Islands and mainland Spain.

How it works: favourable raw water quality

The desalination system combines existing RO membrane technology from DuPont with existing Norwegian subsea technology used in oil and gas applications over the last two decades.

The standard design has a capacity of 50,000 m3/day, split into modules, and Waterise said a 200,000 m3/day capacity could be reached by connecting four units together.

At a depth of 400m, the plant is connected via an “umbilical connection”, a cable that provides electricity and communication, as well as a pipeline that brings water back to the shore.

“Sub-sea desalination is not an incremental improvement; this is the first game-changer in decades.”

The distance to the shore will depend on the location to reach the 400m depth, but on average, the company said this would be between 5-7km from the shore.

“Sub-sea desalination is not an incremental improvement; this is the first game-changer in decades,” said desalination veteran Borja Blanco, CEO of consultancy Aqua Advise and chief commercial officer at Waterise.

He told Aquatech Online: “The raw water quality at a 400m depth is very favourable. This avoids algal blooms, jellyfish or other contaminants, which often reduces terrestrial plants availability. It means there is no annual downtime due to seawater quality issues and also eliminates the need for expensive pre-treatment.”

Results from the Boknafjorden trial have shown an energy consumption of 1.8-2 kWh/m3 compared to 3.3 to 3.6 kWh/m3 for land-based, terrestrial desalination.

“A very simple intake means there’s no need for a long-pipeline, thereby immediately saving 5-20 per cent of the traditional CAPEX costs,” adds Blanco.

Disposing of the brine disposal challenge

A waste product from the water desalination process, brine has been called “one of the world’s great environmental challenges”.

Existing brine disposal methods include pumping it back into the sea or catchment areas where the salt is harvested. Waterise believes the low recovery design element, together with the depth, can avoid the brine disposal challenge.

“Conventional desalination plants are discharging brine that is nearly twice the salinity of the seawater they are treating,” adds Blanco.

“The sub-sea approach is only 1.3 times [the salinity of seawater]. This is mainly because of the low -recovery design: instead of 65 bar pressure needed with conventional plants, we’re working at 40 bar because we’re lowering the recovery and the membranes.”

Blanco adds that no chemicals are used in the treatment, which means “from a footprint, energy and brine advantage, we have a huge environmental benefit”.

“Our ambition is to sell water, not the plant, in a private-public partnership that will operate like a BOT (Build-Operate-Transfer),” he added.

The proving ground for desalination innovations

Waterise is not the first company to attempt commercialisation or sub-sea desalination. For example, in the Netherlands, Dutch start-up Waterfountain developed an unmanned, modularised desalination system that it claims can produce 30,000 m3/day.

Rather than the Waterise system that connects to the shoreline, this system instead is connected to a 200 ft floating vessel, which it said could be powered by liquified natural gas (LNG).

In the 1990s, Global Water Technologies patented a subsea process. Later an EU funded research project, including the Italian company Enel, investigated the feasibility of a ‘Submarine seawater reverse osmosis desalination system’.

“The idea behind this development is intriguing but successful implementation has eluded a number of previous attempts.”

Previous efforts have promoted barge or ship-mounted systems on platforms, which are considerably different to the Waterise approach that wants to locate its solution 400m underwater.

Dr Graeme Pearce, principal at Membrane Consultancy Associates, said there had been notable developments in this space commercial success has not been forthcoming.

He told Aquatech Online: “The idea behind this development is intriguing but successful implementation has eluded a number of previous attempts to exploit the potential of this concept. However, Waterise combines solid desalination expertise with sub-sea experience, so if anyone can make this work, this team should be able to.

“The efficiency claims make sense. The challenge will be to find a 400m depth ocean location which is close enough to a user that the energy saving will not be dissipated by the transfer cost. If the water has to be pumped for any significant distance onshore (e.g.>100 km), the energy-saving will quickly disappear.”

Pearce added: “Of course, the comparison is much more complicated than this with a number of pros and cons, and it will be interesting to see where the balance lies for some actual commercial opportunities.”

Related content

- Mike Dixon: Creating an AI “Netflix model” for desalination

- Qatar desalination trial provides hope for thermal innovation

- Paul Buijs: Busting four desalination myths

- Explore all our coverage related to desalination