UV-C LED technology has come a long way in a few years and is set to replace mercury-based UV treatment lamps with the UN Minamata convention on Mercury helping to reduce the use of the metal. Aquatech Online spoke to Oliver Lawal of AquiSense Inc, and Matt Simpson from Nuuv about the current market conditions for UV-C LED technology and where the future is heading.

UV-C technology, in general, has been used for disinfection purposes. UV-C light operates in the 100-280 nm light range, which is effective at disrupting the DNA and RNA of bacteria and viruses. This makes it ideal for disinfection applications such as treating drinking water and wastewater.

Traditionally, UVC treatment used systems with mercury-vapor lamp technology as the UV source. These have been applied in many industrial and commercial processes within food and beverage, pharmaceuticals, food services, and data centres.

However, these have a number of drawbacks, including high energy use and pollution risks.

Lawal explained: “It’s hard to see how mercury can maintain its place indefinitely in UV light sources. The UN Minamata convention on Mercury is in force and effectively set a timer for the switch to non-mercury UV light sources.”

UV-C LED systems are semiconductor devices that are made up of multiple layers of substrate materials. They can be designed so that a wavelength can be inputted and emit photons in the UV-C range that can be used to stop the replication of bacteria.

Lawal explained to Aquatech Online that since UV-C LED water treatment products have been available commercially, by far the main applications have been in smaller point-of-use products.

He said: “These are typically under five litres per minute (lpm), contain one or more LEDs and integrated electronics. They vary in complexity, with the high-end ones including real-time UV intensity monitoring, other feedback signals and 3rd party certifications to standards such as NSF. These are increasingly common in water coolers, beverage dispensers and caravans/RVs.”

You can develop treatment processes which are much more adaptable - Simpson

Another advantage UV-C LED systems have over legacy systems is that there is no warm-up time. Once an LED system is turned on it can start disinfecting and treating water. And it can adapt to the water conditions.

Simpson told Aquatech Online that technology is infinitely adjustable: “You can develop treatment processes which are much more adaptable and ultimately present a savings in energy and significant operator advantages. Outside the municipal application that becomes even more true.”

He added: “It just watches what everything else does and adapts. If you’ve got low flow, it winds itself down. It's an instant on off. And if you’ve got high flow, it can wind itself up. It does this in milliseconds. It's highly controllable. The sources are very stable.”

Simpson explained that the way that regulation is going, in terms of public health and environmental protection, when combined with the challenges faced in both the supply chain and the water industry, both drive towards low energy, low chemical, low residual water treatment. Which means ultraviolet water treatment, no matter how it is delivered suits public health and environmental protection targets as well as the carbon objectives of water treatment.

We are seeing more complicated water cycling is leading to more complicated treatment challenges - Simpson

He added: “We are seeing more complicated water cycling is leading to more complicated treatment challenges. And going after those with a traditional approach of more energy and more chemicals is creating more problems not more solutions.”

“Ultraviolet technology is a good way of simplifying that chain and achieving good outcomes without the complications of disinfection byproducts.”

The ability to treat water without chemicals is another major reason to use UV-C LED technology in wastewater applications. Real-time measuring and monitoring are other factors that makes the technology applicable in water treatment, whether for point of use systems or for larger applications.

Simpson explained: “The technology is very applicable in our discharge to wastewater because we are trying to understand the implications of either direct discharge to receiving waters or water reuse applications. Whether that is indirect reuse through aquifer recharge or more direct reuse, potentially up to potable reuse of waste water. The ability to treat water without chemicals really simplifies that process and means we don't have those negative impacts on discharging heavily treated residual laden waters.”

Real-time monitoring adds to our understanding of the water being treated and the effectiveness of the process.

There is a vast depth and breadth of science involved in characterising the UV dose response of different pathogens - Lawal

“You can very good data rich measurements out of UV measurements; you can use basic measurements for adsorption and fluorescence, for example. It’s an ‘electrons in, measurement out’ parameter, allowing for continuous water quality monitoring”

Lawal explained that industrial and municipal installations with UV-C LEDs are well into the early-adopter phase with over 30 documented installations currently managing flow rates over 400 lpm in Europe, US and Asia. These range from drinking water, wastewater, reuse and various industrial applications.

The sheer range of potential applications, from 5 lpm to 10,000 lpm units requires a high level of engineering, Lawal explained. “There is a vast depth and breadth of science involved in characterising the UV dose response of different pathogens to identify how much UV is required. It is more than just a light in a tube!”

Another challenge is the fact that there is no easy way to validate the technology’s success.

Simpson explained: “One of the big challenges is getting people comfortable with the fact that you validate the equipment, you maintain it to validation, you switch it on, and then you're confident it's working.”

You validate the equipment, you maintain it to validation, you switch it on, and then you're confident it's working - Simpson

This creates a confidence gap for those new to the technology. “We like to watch a level go down or we like to watch a color change. or we like to be able to measure a downstream parameter. There isn't an equivalent in in ultraviolet. We measure the UVT and the flow rate of the incoming water,” added Simpson.

But there is no residual chemical to measure downstream, no marker or footprint. Simpson continued: “We're used to pumping chemicals, shoveling carbon, or whatever, into water, which we can measure downstream, and we can say, ‘I had a great big tank of reagent A, I've pumped it into here and I no longer have reagent A, I've done something and we're all good’.”

Where distribution networks are well-maintained and regulated, like in the Netherlands where there is no chlorine treatment and UV is used widely, this confidence gap rarely exists, whereas somewhere like the UK, the risk of reinfection later in the network means chlorine is still widely used.

UV-C light is perfect for inactivating microbes in a column of water, but it cannot filter out contaminants such as heavy metals or minerals. It also has no residual effect on the water it treats, which means that once the water has passed the LED it can be reinfected further along the treatment process.

Wastewater with high levels of turbidity can also present significant challenges for UV-C LED treatment.

Lawal believes that there is still so much growth capacity for drinking water and wastewater disinfection globally.

He said: “Ageing infrastructure and urbanisation will be growth drivers. There are also many important challenges that advanced water treatment technologies are helping to address. Advanced Oxidation Processes (AOP), Water Reuse and even PFAS reduction, often utilize UV as a step in the treatment process.”

Advanced Oxidation Processes (AOP), Water Reuse and even PFAS reduction, often utilize UV as a step in the treatment process - Lawal

This versatility will help UV-C LED adoption, agrees Simpson: “There isn't any particular sector of the water treatment industry that it doesn't apply to. There aren't many technologies that are applicable to micro pollutant removal, drinking water disinfection, environmental discharge, wastewater disinfection, interstage RO treatment.”

He added: “You can use UV-C LED as an interstage. It’s not a standalone miracle treatment. Instead, it needs to be seen as a strong link in a chain and in that sense, it does need to be understood and designed within a treatment system carefully.”

Given it’s solid-state, controllable and safe operation, Simpson believes there could be another application for UV-C LED technology: “It could be containerized and taken outside of the treatment works, as a distributed emergency response, such as in the case of a cryptosporidium outbreak.”

Both Lawal and Simpson agree that the technology has a future in advanced oxidation processes and photo catalytic processes.

If we can develop water treatment solutions which are ‘electrons in, treatment outcomes out’, then you can achieve many of the goals of water treatment - Simpson

He explained: “We ran a pilot process looking at removing taste and odour compounds with an advanced oxidation process which was highly effective. We’ve also developing a technology which is a photocatalytic approach, with novel optics and novel manufacturing, to be able to optimise the photon to surface ratio. These are really exciting development opportunities.”

The future for UV-C LED technology could look very different to its current use. Simpson added: “This is looking at totally new forms for water treatment. If we can develop water treatment solutions which are ‘electrons in, treatment outcomes out’, then you can achieve many of the goals of water treatment, which is less energy, less chemicals, less environmental impact.”

Nuuv is currently working on a UV254 monitoring device, which has been field-trialed with both United Utilities and Northumbrian Water in the UK. The device helps to optimize existing UV equipment, monitor disinfection byproducts, where chlorine or oxidizers are being used as disinfectants. especially given the UK’s section 28 PVP reporting requirements.

Simpson explained: “The performance of equipment is often held back by the reliability of the control point, the input device. And there's this need to have confidence in your system which comes from your ability to take accurate measurements of your initial conditions and often those devices that were taking those initial condition measurements were highly variable and highly inaccurate.”

The device is being trialed primarily in drinking water treatment to help report against regulatory requirements. However, Simpson added: “I think it's also potentially a very useful device for optimising chemical dosing control at the front end of treatment works. So, the ability to make savings in how people are handling their coagulation control and chemical dosing.”

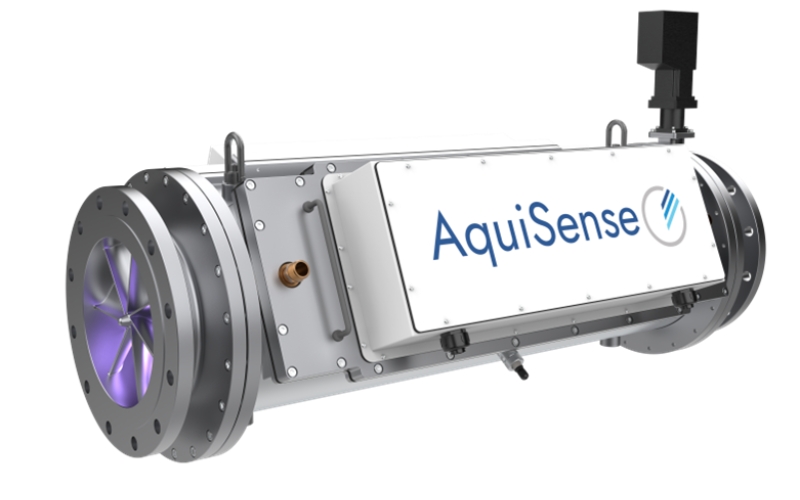

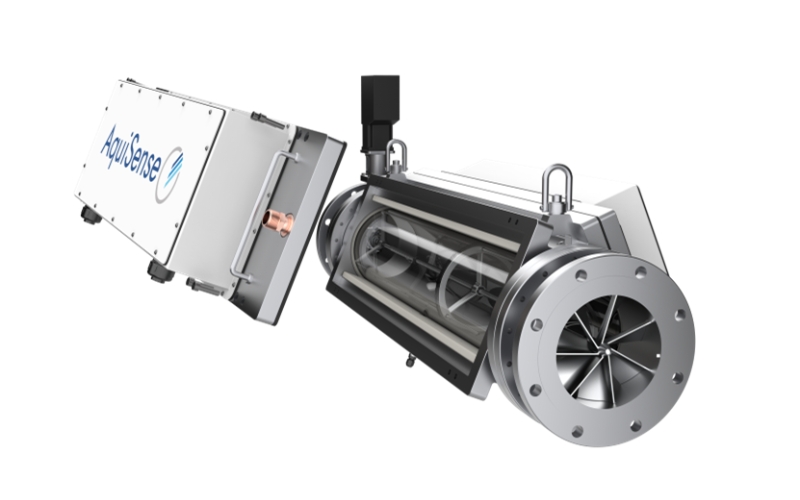

A PearlAqua Kilo unit integrates LEDs into a unique and compact design without the use of chemicals or mercury-based UV lamps. This will ensure the water treatment in the facility is future-proofed against any regulatory changes affecting mercury usage. The PearlAqua Kilo offers municipal and industrial level disinfection with flowrates up-to 6 MGD (22,712 m3/D).

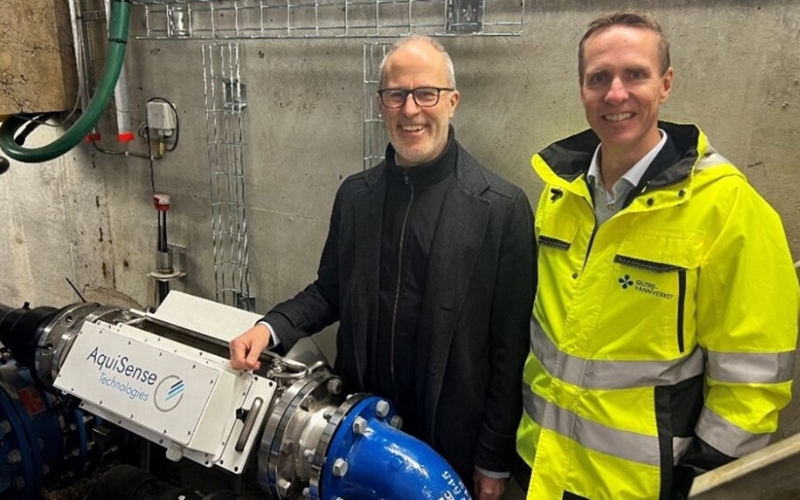

The units have been used in a collaborative project involving Norwegian utility Glitrevannverket, Danish engineering consultancy Rambøll and UV-C LED market leader AquiSense Incorporated. The project is testing UV-C LED multiple units designed for municipal and industrial water disinfection at the Setervann water treatment facility near Asker, Norway.

The PearlAqua Tera is one of the first full-scale UV-C LED reactors for municipal use. AquiSense developed the PearlAqua Tera to handle municipal and industrial level disinfection flowrates and to withstand the environmental conditions for an outdoor municipal water treatment reactor.

The system has been used by the Las Vegas Valley Water District to disinfect groundwater. The PearlAqua Tera units in Las Vegas were also fitted with the PearlWiper, AquiSense Inc’s new self-cleaning mechanism, designed to address one of the most challenging aspects of water and wastewater disinfection systems – fouling and maintenance.

The PearlWiper utilises advanced automation and real-time monitoring to clean the system’s critical quartz window components, reducing the need for manual intervention for cleaning and system downtime. In addition, advanced thermal management with the PearlAqua Tera’s UV-C LED lamp design, the light emitting surface is completely isolated from the thermal emitting surface. This allows users to limit heat induced fouling and maintain stable thermal management under all ambient and process water conditions.

A unique design, all replacement parts are designed to be isolated from the reaction chamber while still pressurized allowing operators to simply remove a few external fixtures to remove the lamp assembly and reattach a new lamp module.

The technology allows for all electronic lamp drivers to be housed in the same assembly, thus negating the need for an additional ballast cabinet and interconnecting cabling. This significantly reduces the system footprint, installation complexity and cost. No concern for handling or breaking a mercury lamp breaking and no mercury-based health hazards to employees or, worst case, the downstream water flow.