From water purification to pharmaceutical production, membrane technology plays a crucial role in various industries. We highlight some of the latest developments to combat fouling associated with the process and companies reshaping the landscape of membrane technology.

After many years of development, the market for membranes in the water industry may be relatively mature and settled. Yet, operational challenges such as fouling and new application demands, including organics removal, have sparked pockets of dramatic development.

Dr Graeme Pearce, a membrane technology specialist with 40 years’ experience in the membrane industry, believes there are two areas with unmet needs:

Speaking to Aquatech Online, he says: “Although good design and operation should control the problem with current polymeric membranes, it could be the use of ceramics which finally introduces a robust solution.”

Mature applications include straightforward filtration needs in drinking water and wastewater, including Membrane Bioreactor (MBR), and pre-treatment in desalination. If the feedwater has a relatively low fouling propensity, current polymerics are well suited to the challenge and have steadily improved with time.

“However, fouling by particulates and adsorptive fouling from organics present a serious challenge in some cases,” adds Pearce.

Despite the great headway in tackling membrane fouling and organic material accumulation, challenges remain. The development of alternative membrane materials has shown promise in both addressing fouling challenges, and making membranes more suitable for dissolved organics removal, thereby addressing the new application focus.

Pearce believes this could help to open the door to ceramic membranes. “Polymeric membranes' hydrophilicity enhancements degrade over time, leaving them vulnerable to organic fouling,” he says.

“Chemical cleaning exacerbates this issue. Ceramic membranes offer inherent hydrophilicity and adjustable surface charge, resisting fouling and chemical degradation. Graphene membranes show promise but require further development. Ongoing research is crucial for optimising these solutions.”

Over the years, significant advancements have propelled membrane technology forward, enhancing efficiency, sustainability and versatility. One of the most advanced developments in membrane technology is the integration of nanotechnology.

By leveraging nanomaterials such as carbon nanotubes, graphene and nanofibers, researchers have achieved remarkable improvements in membrane performance. These nanostructured membranes offer enhanced selectivity, increased permeability and superior fouling resistance compared to traditional materials. By incorporating nanotechnology, membranes can resist fouling caused by organic material buildup, prolonging their lifespan and reducing maintenance requirements.

The advent of “smart membranes” also marks a significant step forward in membrane technology, designed to respond to external stimuli such as pH, temperature, and pressure, allowing for dynamic control over filtration processes.

By adapting their permeability in real-time, smart membranes can mitigate fouling caused by organic material buildup, ensuring consistent performance over time. Moreover, these membranes pave the way for autonomous filtration systems capable of self-regulation and optimisation, further reducing the risk of fouling.

Inspired by nature, biomimetic membranes mimic the structure and functionality of biological membranes found in living organisms. By incorporating biomimetic principles, researchers have developed membranes with unprecedented efficiency and versatility.

For example, researchers at Harvard's Wyss Institute for Biologically Inspired Engineering have been working on biomimetic membranes inspired by the structure of cell membranes. Their work involves creating synthetic membranes that mimic the selective permeability and self-repair mechanisms found in biological membranes. These could be applied to improve the efficiency and selectivity of water purification processes, such as filtration and reverse osmosis, thereby addressing challenges related to access to clean drinking water.

Massachusetts Institute of Technology (MIT) researchers have developed biomimetic membranes inspired by the structure of aquaporin proteins found in cell membranes. These membranes are designed to selectively filter molecules based on size and charge, mimicking the function of natural aquaporin channels.

MIT's research on biomimetic membranes inspired by aquaporin proteins could lead to advancements in desalination technology, allowing for more efficient removal of salt and contaminants from seawater to produce freshwater for consumption and agricultural use.

These membranes exhibit enhanced selectivity, robustness, and antifouling properties, making them ideal for applications ranging from biomedical devices to food processing. By mimicking natural filtration mechanisms, biomimetic membranes can effectively combat fouling caused by organic material buildup, ensuring reliable performance even in challenging environments.

The emergence of 3D printing and additive manufacturing technologies has also revolutionised membrane fabrication processes. By harnessing the power of digital design and rapid prototyping, researchers can create complex membrane structures with precise control over pore size, morphology, and surface properties.

This enables the development of customized membranes tailored to specific applications, optimising performance and reducing manufacturing costs. Additionally, additive manufacturing allows for the integration of functional additives and nanomaterials directly into the membrane matrix, enhancing fouling resistance and prolonging membrane lifespan.

Membrane distillation represents a promising alternative to traditional separation processes, offering advantages such as low energy consumption and minimal environmental impact. In membrane distillation, a hydrophobic membrane separates hot and cold streams, allowing volatile components to evaporate and be collected as permeate. This process is particularly well-suited for concentrating heat-sensitive substances, treating brackish water, and recovering valuable solvents from industrial effluents.

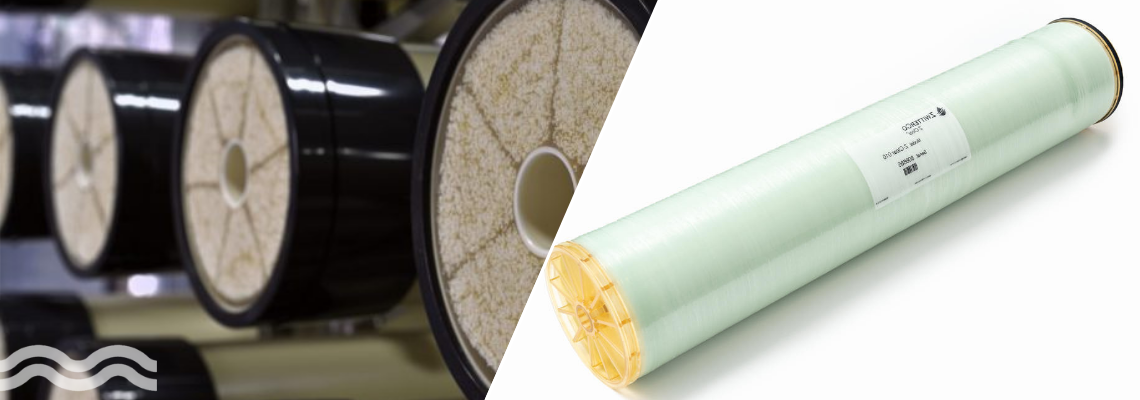

ZwitterCo brackish water reverse osmosis (BWRO) membranes

ZwitterCo’s new brackish water reverse osmosis (BWRO) membranes are organic fouling-immune brackish water membranes that reduce cleaning frequency by up to 90 per cent, which the company claims results in lower operational costs while delivering reliable BWRO performance.

Membrane fouling and degradation from frequent cleaning have plagued the industry, causing excessive downtime, increased operational costs, and shorter membrane lifespan. Globally, there are tens of thousands of industrial BWRO systems that process surface water feeds and face challenges from natural organic matter (i.e. color bodies) and biogrowth, which adhere to the membrane surface and impede performance.

ZwitterCo raised one of the largest Series A funding rounds in history for a water technology company to help with the project.

Other high-fouling applications for BWRO membranes include secondary effluent from wastewater treatment systems and effluent polishing. Growing demand for wastewater reuse is driving the need for new BWRO membranes that overcome these classical fouling challenges.

ZwitterCo says its zwitterionic membrane technology directly solves the long-standing challenges of maintaining BWRO systems. With their immunity to irreversible organic fouling, the BWRO elements have been shown in testing to restore membrane performance with only a water flush, even after filtering high-fouling streams. This enables longer run-times between required maintenance, full performance restoration, and longer membrane life.

Hydranautics Low Fouling Composite (LFC) elements combine neutral surface charge and hydrophilicity, providing what it says is significant reduction in fouling rates and increasing membrane efficiency by restoring nominal performance after cleaning.

This membrane, it says, is well suited for the treatment of difficult feed waters for numerous municipal and industrial applications, which up to now required significant feed water pre-treatment upstream of any composite reverse osmosis membrane.

Through its collaboration with Nitto and the implementation of its membrane solutions, Hydranautics contributed to a resilient and environmentally conscious water supply infrastructure for the city of Tocopilla in Chile. Hydranautics provided reverse osmosis membrane systems tailored to address the specific challenges faced by Tocopilla in securing a sustainable source of drinking water. SWC6-LD membranes were used for the desalination plant's needs, citing its unique combination of high flow, lower energy requirements and low salt passage.

Hydranautics ensured that Tocopilla could efficiently and effectively turn seawater into safe, clean drinking water using the membrane system, which not only facilitated high levels of water production but also minimised energy consumption and maintained low salt passage, meeting Tocopilla's stringent requirements for sustainable water supply.

This membrane technology allowed Tocopilla to reduce its reliance on surface water sources, which were vulnerable to pollution and environmental degradation, while also providing a climate-independent water source to meet the community's present and future needs.

The Hollow Fiber Nanofiltration (HFNF) membranes by NX Filtration, have been designed to combat fouling challenges within the water treatment process.

Engineered with a hollow fiber configuration, these membranes offer unparalleled resistance to fouling while effectively removing organics and salinity from water, minimising the need for extensive pre-treatment.

At the heart of the HFNF membranes lies a patented layer-by-layer deposition process, ensuring precise rejection and flux properties that remain unaffected by fouling agents. This innovative approach extends membrane lifespan, delivering consistent and reliable operation in the face of fouling challenges.

The HFNF modules feature an open, low fouling construction devoid of spacers, simplifying maintenance and ensuring uninterrupted operation even in the harshest conditions.

In conjunction with the HFNF membranes, NX Filtration has also created a Projection Tool to provide valuable insights into fouling dynamics, empowering users to make informed decisions and optimise performance in their water treatment processes.

NX Filtration has supported its partners to minimise their carbon footprint and enable the production of high volumes of clean water across 30 countries worldwide. The direct Nanofiltration membrane (dNF) technology has positioned NX filtration as an innovation and growth disruptor.

One project of note is its work in Sweden. NX Filtration delivered its nanofiltration membranes for the removal of micropollutants and nutrients to the RecoLab project to efficiently recycle greywater, blackwater and food waste in Helsingborg.

To date the company says the project is operating stable. The dNF40 membrane modules of NX Filtration have proven to be very reliable in producing high quality water, it says, and the total system is producing biogas and fertiliser and recycling 80 per cent of greywater. The project contributes to a lower carbon footprint, increased renewable energy output, nutrient and water re-use.

DuPont's B-Free solution is the outcome of what it says is several years of research and development. Its technology is designed to tackle the problem of biofouling in reverse osmosis systems when organic matter like algae and bacteria build up and hinder the system's performance. Instead of using chemicals, B-Free relies on a vessel-based media technology that creates an environment hostile to the growth of these organisms. This makes it suitable for use in both drinking water and industrial applications.

Before water enters the reverse osmosis process, it passes through the B-Free system, where a constant biostatic environment is created. This environment prevents the harmful effects of biofouling by allowing a layer of biostratum to grow evenly between the media top layer particles. This layer acts as a barrier, ensuring that the discharged water remains biostatic even during system startup. Once this biostratum reaches a certain critical mass, it is flushed out from the top of the system, while the media is retained for continued use.

The DuPont technology underwent successful testing at the Masplomas desalination plant in Spain, conducted by water company Elmasa. Throughout an 18-month trial period, the company says B-Free demonstrated its effectiveness in completely eliminating biofouling. This allowed the pilot plant to operate smoothly without encountering issues caused by biofouling. In contrast, the full-scale plant running in parallel continued to experience the negative impacts of biofouling.

The advancements represent just a glimpse into the exciting possibilities offered by membrane technology. By incorporating innovations such as nanotechnology, smart membranes, biomimetic designs, additive manufacturing, and membrane distillation, researchers are making significant strides in combating fouling and organic material buildup, thereby enhancing the efficiency, sustainability, and reliability of membrane systems.

Yet, as Pearce concludes, ongoing research is crucial. As these technologies continue to evolve, we can look forward to even greater breakthroughs in the field of filtration, driving positive impacts across industries and addressing some of the most pressing challenges facing our planet today.