Solar power converts sludge to hydrogen and feed

A novel technology that uses solar power to convert sewage sludge into both green hydrogen and animal feed has been demonstrated by scientists at Nanyang Technological University in Singapore (NTU Singapore).

The need to transform sludge

The authors suggest that the research is an attempt to overcome a number of issues related to wastewater treatment. First, the amount of sludge being produced is ever-increasing as populations grow and urbanisation accelerates. Second, the very nature of sewage sludge - its ‘complex and resilient’ structure - makes any treatment and attempts to retrieve or reclaim useful by-products expensive, energy-intensive and environmentally challenging. Third, there is the ongoing question of what can be reclaimed and reused from sewage sludge and whether these things can be done in cost-effective and efficient ways.

In the report, the authors of the research state: “Here we present an integrated mechano-electro-bioprocess that valorises [adds value] sludge with minimal environmental impact.”

The process converts sewage sludge into green hydrogen and animal feed.

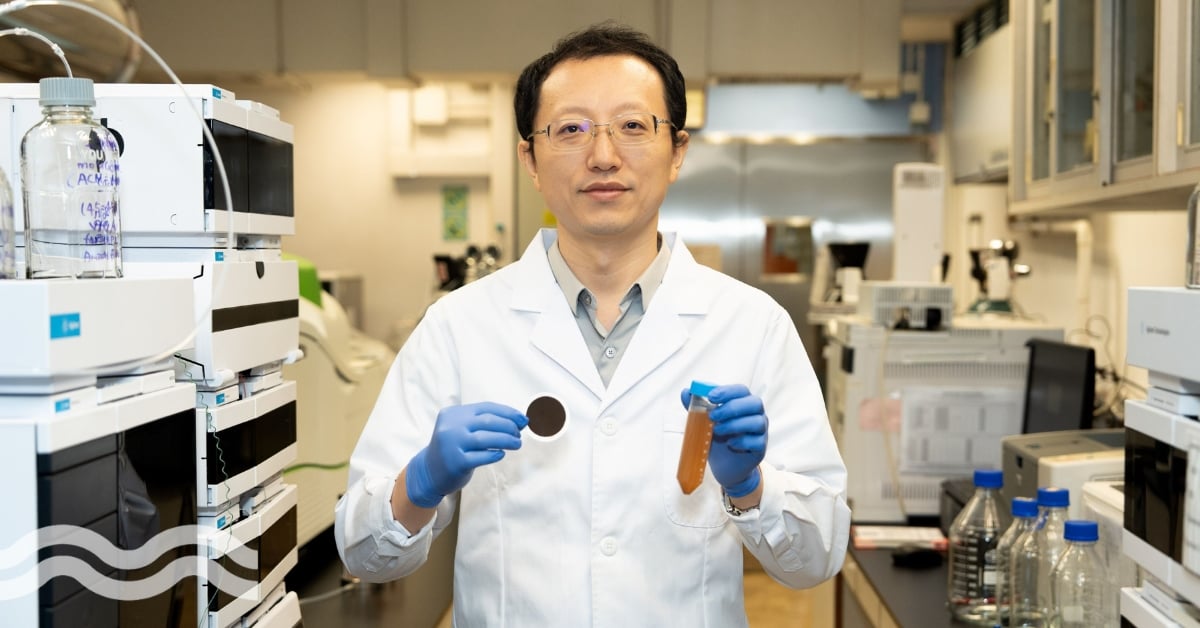

Lead researcher, associate professor Li Hong from NTU’s School of Mechanical and Aerospace Engineering (MAE) and the Energy Research Institute @ NTU (ERI@N) told media, when announcing the success of the research: “Our method transforms waste into valuable resources, reducing environmental damage while creating renewable energy and sustainable food. This exemplifies the circular economy and contributes to a greener future.”

How does the process work?

The research which aligns with the university’s mission to address humanity’s greatest challenges, such as climate change, is published in Nature Water.

According to UN-Habitat, more than 100 million tonnes of sewage sludge are generated globally each year, with the amount increasing annually. To tackle the problem of unwanted and difficult to treat sewage sludge, the research team at NTU created a three-step solar-powered process that integrates mechanical, chemical, and biological techniques.

The researchers developed a three-step process:

First, it begins by mechanically breaking down the sewage sludge by applying a chemical treatment that helps to separate harmful heavy metals from organic materials, including proteins and carbohydrates.

Second, a solar-powered electrochemical process uses specialised electrodes to transform the organic materials into valuable products, such as acetic acid – which is a key ingredient for food and pharmaceutical industries – and hydrogen gas, a clean energy source.

The third and final step involves introducing light-activated bacteria into the processed liquid stream. These bacteria convert nutrients into single-cell protein suitable for animal feed.

Proof-of-concept tests at the university revealed that the process recovers significantly more resources, completely removes heavy metal contaminants, has a smaller environmental footprint, and offers better economic feasibility.

How efficient is the process?

The researchers claim their method achieves ‘nearly complete recovery of organics’, amounting to approximately 91.4 per cent of total organic carbon (TOC), compared to approximately 50 per cent recovered from anaerobic digestion techniques. Sixty-three percent of these organics are then converted into single-cell proteins in a tandem process for use as animal feed.

At the same time, heavy metals in the sludge are concentrated and stabilised, producing green hydrogen with an efficiency rate of approximately 10 percent solar-to-hydrogen (at just under 13 litres per hour). The research time claims that the process is around 10 per cent more energy efficient than conventional hydrogen generation methods.

Analysis of the process suggests a 99.5 per cent reduction in carbon emissions and a 99.3 per cent decrease in energy depletion compared to conventional anaerobic digestion.

Co-lead researcher, Professor Zhou Yan from NTU’s School of Civil and Environmental Engineering (CEE) and Nanyang Environment and Water Research Institute (NEWRI) said: “Our solar-powered process demonstrates how we can tackle multiple challenges at once – turning a difficult waste product into clean energy and nutritious protein. By integrating mechanical, chemical, and biological approaches, our method has successfully addressed pollution and resource scarcity, offering a new sustainable strategy in wastewater management.”

Challenges ahead for real-world applications

Dr Zhao Hu, research fellow at NTU, and lead author of the research, told media: “We hope that our proposed method shows the viability of managing waste sustainably and shift how sewage sludge is perceived – from waste to a valuable resource that supports clean energy and sustainable food production.”

The team adds a note of caution to its impressive results. It is not yet known how scalable the technology and process is, with more studies needed to establish whether it can be achieved. One of the main challenges is the cost of using electrochemical processes in large wastewater treatment plants.

However, as the team notes, “this mechano-electro-bioprocess offers a promising path towards sustainable development,” of solar-powered resource recovery from sewage sludge.

(Image Credit: Nanyang Technological University)