From toilet paper to biopolymer: a circular economy trial

Technology that captures toilet paper from untreated sewage to turn it into biopolymers, such as glucose, is being trialled at Blackburn Wastewater Treatment Works as part of a €7.8m project funded by UK regulator Ofwat’s Innovation Fund.

Dutch and British collaboration tackling sewage waste

Although the project is being trialled in the UK, the technology was developed by Cellvation, which is a joint venture based in the Netherlands between Recell Group and CirTec. Working alongside United Utilities, the project forms part of the Biopolymers in the Circular Economy (BICE) project.

Lisa Mansell, chief engineer for Innovation and Carbon at United Utilities, told Aquatech Online: “This project is demonstrating that we can capture useful by-products from sewage which can then be used as lower carbon alternatives to conventional polymers and plastics.”

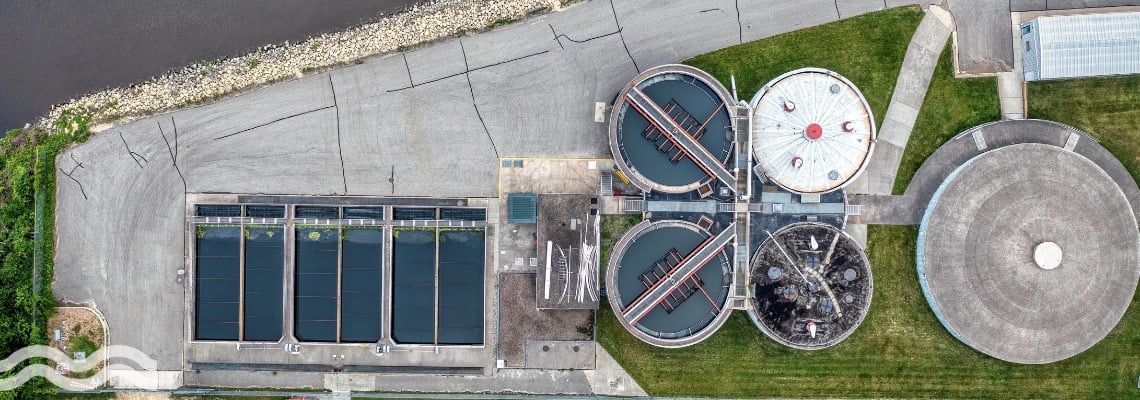

She added: “Blackburn Wastewater Treatment Works serves a population of around 200,000 people – this means that millions of sheets of toilet paper end up there every day. Toilet paper is mainly made from trees or other plant materials, and these all contain cellulose, which is a form of glucose.”

Lisa Mansell, chief engineer for Innovation and Carbon at United Utilities

How does the technology work?

It works by capturing toilet paper from untreated sewage and extracting the naturally occurring glucose. First, it filters and compacts the paper, then it adds enzymes and chemicals, before heating the mixture for over 48 hours to transform cellulose into glucose.

A second technology will also be trialled to recover biopolymers from the sewage sludge that is left at the end of the treatment process.

Biopolymers are naturally occurring and include substances such as starch, gelatine, collagen and cellulose. These biopolymers can be used as low-carbon products with various applications, such as the production of biofuels, and as an alternative material for manufacturing products like bioplastics and more sustainable detergents.

Long-term benefits of capturing glucose

Cellvation explained why it thinks this project is so important in its social media pages: “The BICE project showcases the transformative potential of circular technologies to deliver substantial carbon reduction benefits. Not only for the water sector, but across multiple industries in the UK.”

So far, the trial has demonstrated that the technology has the potential to improve the efficiency of the wastewater treatment process by increasing capacity and reducing energy use.

United Utilities is also working with other partners to explore further uses for the glucose, including whether it could replace some of the oil-based biopolymers that are currently being used in the wastewater treatment process.

Mansell added: “Our project will explore the economic benefits for water companies as well as determining any social and carbon value delivered by these approaches and develop a strategy for end of waste to enable water companies to explore new markets for recovered products.”

Scaling up award-winning process

Although the trial is the first to take place in the UK, the technology has been slowly scaling since 2016, when part of a bicycle path in Friesland was successfully constructed using cellulose fibres recovered from toilet paper. This led to the first pilot of the technology in a treatment plant, the SMART-plant (Scale-up of low-carbon footprint Material Recovery Techniques in existing wastewater treatment Plants) at Geestmerambacht, Netherlands. Later that year, the technology received the Overall Aquatech Innovation Award 2017.