Arthur Umble: Unlocking water resources using biomimicry

Arthur Umble

Arthur Umble

Why the term ‘wastewater’ is outdated

A truly circular economy must include water resource recovery, and designing as nature is the best process to follow. By Arthur Umble.

The term “wastewater” is outdated. For years, engineers like me designed wastewater treatment plants (WWTP) for communities around the globe. That traditional treatment was all about disposal. No thought was given to recovery of resources, including the water.

It was very linear: waste in, waste treated, and the cleaned “waste” sent into the environment.

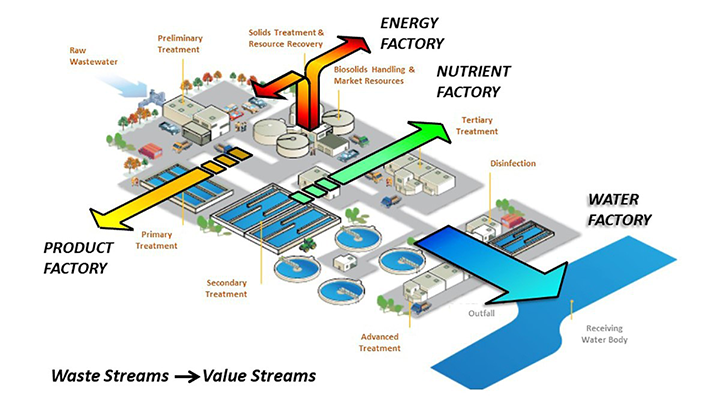

Today, it’s much more appropriate to think of those facilities as water resource recovery factories (WRRF) because most of what is in wastewater is not waste. It shouldn’t be about treatment and then disposal. It should be about recovery.

As Earth's natural resources become scarce, resource recovery is our industry's link to the circular economy. Not only is resource recovery here to stay, but it's also growing.

What’s in the wastewater

“Honestly, most people don’t give much thought to what’s in their community’s wastewater. The thinking is: there is no value in “waste.” But that’s incorrect.”

Honestly, most people don’t give much thought to what’s in their community’s wastewater. The thinking is: there is no value in “waste.” But that’s incorrect.

Raw wastewater entering a WRRF has several potential value streams: water, energy, nutrients, and products.

Water: Potable and non-potable water. Current uses include industrial cooling, agriculture and landscape irrigation, and aquaculture. We can and should recover every drop of water we can. Whether it’s a water-rich area like Minnesota or a water-poor area like Phoenix, Arizona, there is always a use for all water we recover.

Energy: Transportation fuels, including biofuels, and power and heat. About 20 per cent of energy in wastewater is the form of chemical energy; about 80 per cent is heat. A lot of resource value is in these wastewaters.

Nutrients: Food/feed. What's recovered from wastewater can help sustain our global population through fertilization for food production. Nutrients, which are abundant in waste, are essential to the global sustainability of feeding the world.

Products: A wide variety, including pharmaceuticals, industrial chemicals, performance materials, metals, and fertilizers. Here we're looking mostly at the carbon-based products in our waste streams. Carbon is organic, and we can use it to replace plastics by building bioplastics from these polymers. We can support the biofuels industry, the pharmaceuticals industry, etc. These products all exist.

But how best do we recover those items from the “waste” stream? Turn to nature. It knows what it’s doing.

Managing our resources through biomimicry

Biomimicry is not designing WITH nature but designing AS nature.

Nature has had 3.8 billion years of evolutionary time to develop its means and methods for addressing and solving problems. There is nothing that we have faced in our short human history that is not something that nature has not already seen and solved. We simply must look.

Following nature’s lead can be summed up in the “3 Ms: model, mentor and measure:

- Model: Reconnecting with nature directly. Nature informs the design framework.

- Mentor: Emulating nature’s strategies for survival. Nature teaches us about how to use resources, rather than simply providing us with resources for our use.

- Measure: Those 3.8 billion years of evolutionary development for 30 million known species can be now used as our benchmark for sustainability. Nature knows what works and what lasts—it is the ecological standard.

As we look to nature, there are two paradigms to consider.

The problem: Solution paradigm is the "reactive" paradigm. Here we have a known problem, and we go to nature to see if we can find analogies where nature has developed a solution. Then we take that solution and apply it.

The solution: Problem paradigm is the “proactive” paradigm. Here we focus on observing how nature functions. It provides solutions to us for problems we do not yet know we will incur.

If we daily observe nature (use it as our model), it will mentor us. Nature will essentially say: “Here is how I use available resources.” That’s the proactive way of approaching our challenges.

“Biomimicry is a paradigm for pushing technology to disruptive states, a must for resource recovery.”

Examples of biomimetic technologies

Our industry is only now beginning to understand the opportunities biomimetic principles pose for resource recovery technologies that are disruptive. Here are several examples:

- Microalgae: Microalgae cultured from wastewater is disruptive because it solves multiple problems by what it can do: remove nutrients and produce energy while providing a sink for atmospheric carbon.

- Biopolymers: Building biopolymers from carbon recovered from wastewater is disruptive because of the many uses that can be found for biopolymers that are environmentally beneficial, from bioplastics to biofuels. These products can go into markets - supporting the circular economy. As a side benefit, we are reducing energy use in the plant by not having to remove all the carbon.

- Bioelectrical-chemical Systems (BES): These systems apply biomimicry principle by using the natural processes of transferring electrons that bacteria do when breaking down organic matter. By capturing these electrons, clean, electrical energy can be produced. Interestingly, we can use BES in conjunction with microalgae and produce biopolymers to make chemical products - driving the circular economy. Again, this is a disruptive technology.

Why biomimicry is critical for a circular economy

Biomimicry is our model, our measure, and our mentor to a successful transition of treating wastewater for disposal to it being a driver for a circular economy.

Biomimetic principles are at the core of the technologies being developed to recover the resources embedded in wastewater with the impact to truly disrupt our conventional approaches to the treatment of wastewater.

To become a circular economy, everything must have a value: monetary, health or something else.

Biomimicry is likely the only way we approach treatment that allows us to get the enterprise piece out of our wastewater. It helps us to get nutrients, energy, water, chemicals and products out and into a form that it can be sold.

These are economic benefits for the community. That is really the key. That’s how you get the circular engine going, and that’s our future.

Arthur Umble

Global Wastewater Practice Leader

Stantec