|

Table of contents |

|---|

Often overlooked and misunderstood, check valves play a vital role in water management systems and are a staple in practically every industrial application.

What is a check valve?

A check valve is a component that can be fitted on to the end of a pipe or channel and acts as a one-way/non-return valve that opens under pressure. While water can travel out of the check valve, it cannot travel back through the check valve.

Image credit: Proco Products

Check valves can come in a range of sizes, designs and materials, all of which can have an effect on the efficiency of the component.

While we will mainly look at check valves from the perspective of their application in various water uses, check valves are also used to process a variety of different fluids, materials and gases.

Check valves perform an essential function in preventing reverse flow – where potentially polluted water is allowed to travel back into a system and contaminate clean water resources.

How does a check valve work?

Check valves are a common sight in industrial systems and are used to remove wastewater and other contaminated fluids. Check valves feature a single inlet and outlet where water can pass through it but not back up it, and it is operated by a pressure differential, according to Proco Products.

A pressure differential, in the context of check valves, is when the pressure of the water inside the valve is greater than the pressure keeping the valve closed. When the pressure on the inlet side is greater, the valve opens automatically, allowing the water to pass through it - this is called cracking pressure.

Cracking pressure is a specified minimum operational pressure that determines when the valve will open and allow water to flow.

In a water system, for example, multiple check valves will be placed in a series to prevent any backflow of contaminated water that could compromise clean water supplies. This also helps to reduce the risk of any reverse flow that could result in water hammer.

What is water hammer?

The phenomenon known as water hammer, also known as valve slam, is when flow reverses before the valve is completely closed. Once the valve has closed, the sudden change in flow direction and the velocity results in water hammer.

Water hammer proceeds when water in motion is suddenly forced to stop. When the flow of water at the leading edge comes to a stop, but the water behind it continues to move - it starts to compress.

The build-up of the kinetic energy of the water converts to a high amount of pressure energy, creating a hydraulic shock wave that travels at almost the speed of sound, just less than 343 meters per second, through the pipeline.

When repeated extreme pressure surges in connected piping, valves and pumps, it can cause catastrophic damage and ruptures to a water system and its intricate pipework.

Should water hammer occur, it can completely destroy a system that could cost tens of thousands of dollars to repair.

In the event that water hammer occurs, but a water system continues to operate successfully, the repeated impact of water hammer can lead to systems and components becoming fatigued and could seriously compromise the integrity of a system.

Types of check valves

Check valves have many purposes and roles in a lot of applications – from your home to large industrial wastewater management models.

This means there is a range of different check valves specially designed to suit the requirements of a specific project.

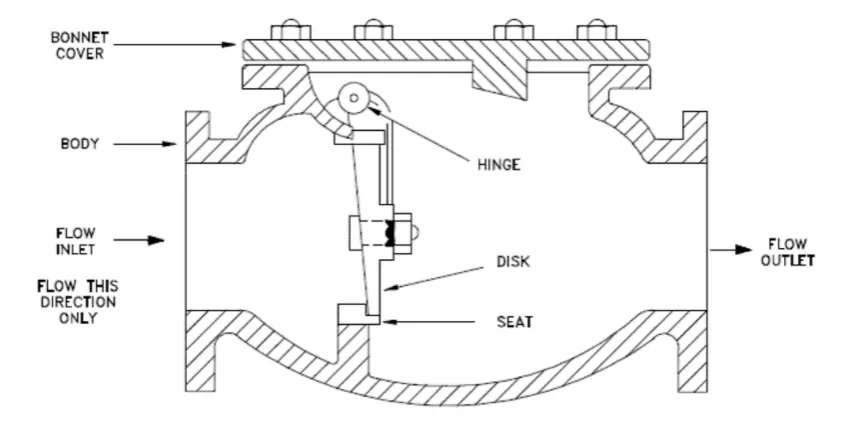

Swing/flap check valves

Swing/flap check valves or PVC check valves are the simplest design of check valves and are used in small homes to large scale industrial plants.

Image credit: DOE Handbook

A metal disc pivots on a hinge or trunnion to prevent reverse flow. Most larger-scale check valves use this design due to their simplicity. With a life span of five to seven years, these valves are often a component that needs to be replaced frequently.

Despite being a popular check valve, due to its cost and simplicity, steel flap and swing check valves can rust, stick and over time become prone to jamming with debris that requires manual cleaning.

When these valves fail, they allow backflow and water hammer to occur. Abrasive sludges and corrosive slurries can create wear and will damage the valves rendering them inoperable.

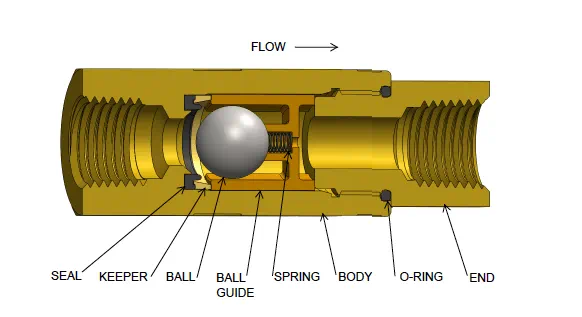

Ball and spring check valves

A ball and spring check valves are known for their durability and how easy they are to install. They operate when the inlet pressure is greater than the cracking pressure, pushing a ball or disc back and overcoming the strength of the spring.

Image credit: Speciality Manufacturing

When the inlet pressure drops below the cracking pressure or backflow occurs, the spring forces the valve to close – stopping the water escaping or travelling back up the pipe.

While ball and spring check valves are known for their reliability, the main drawback to this type of check valve occurs when it needs to be inspected for maintenance. In order to check the valve, it has to been removed completely from the system.

The ball and spring design are used for air check valves. An air check valve has one main function – to allow air flow in one direction whilst preventing air flow from the other side. Air check valves are fitted to air compressors so that it can keep certain part pressurized and others allow other parts to become de-pressurized.

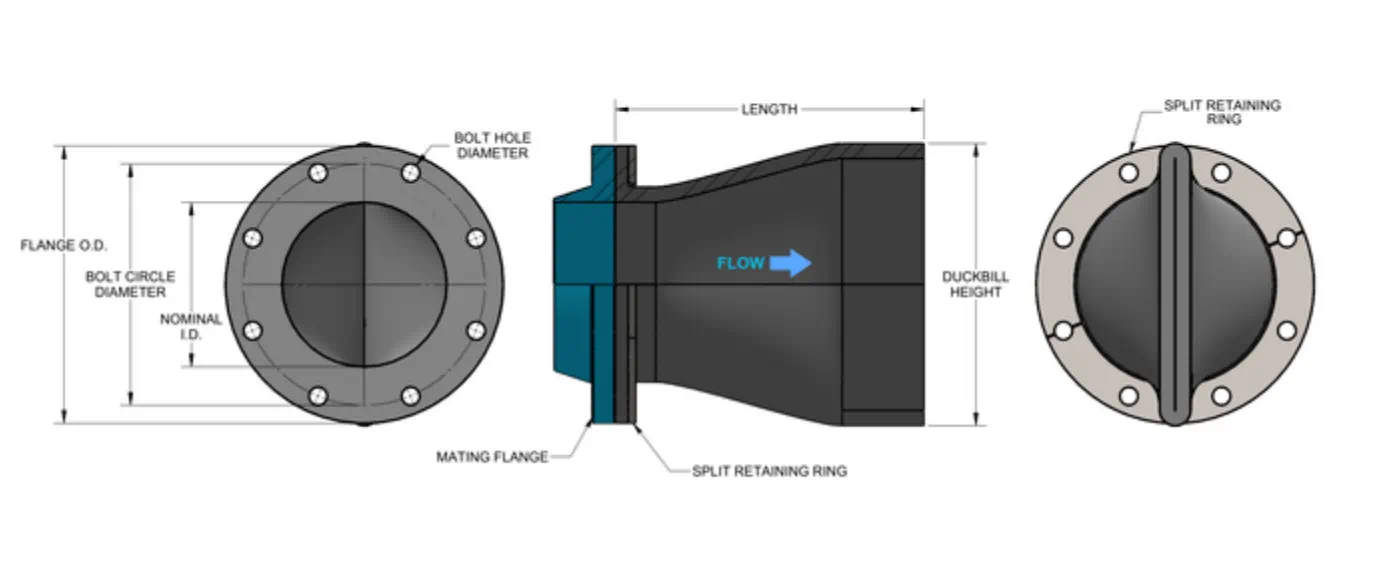

Duck bill check valves

The duck bill check valve came into use in the 1980s and was brought in to replace swing/flap valves. Over the decades it has become increasingly popular in industrial applications.

Working similarly to its namesake, a duck bill check valve open like duck’s bill to allow the water or matter to pass through it.

Image credit: Proco Products

Duck bill check valves rely on a flexible rubber diaphragm which creates a valve that will remain closed unless positive pressure is applied.

Unlike swing/flap check valves, rubber duck bill check valves are increasingly less vulnerable to rusting, they cannot seize or bind and are considered to be one of the most reliable and long-lasting check valves in the market today – with Proco Products valves lasting up to 35 – 50 years.

Duck bill check valves also do not suffer from mechanical wear, and the rubber design allows for greater elastomer innovations and flexibility.

For projects that require a valve to be submerged on the seafloor or underwater, duck bill check valves offer the advantage of being barnacle and algae resistant – an important feature for saltwater projects such as the Marine Wastewater Outfall Diffusion project in 2017.

Another benefit of a duck bill check valve is its ability to cope with water hammer. Cal Hayes, general manager at Proco Products, said the new series 750 duck bill check valve is an example “because it is made out of rubber, instead of creating a huge valve slam back [water hammer], our rubber is inherent to flex so that when pressure is applied to the outside, it is allowed to flex".

This is another form of a surge relief valve that can protect your piping system from the build-up of pressure surges – manufactures such as Emerson Process Management and Daniel Measurement and Control Inc offer valves of this design.

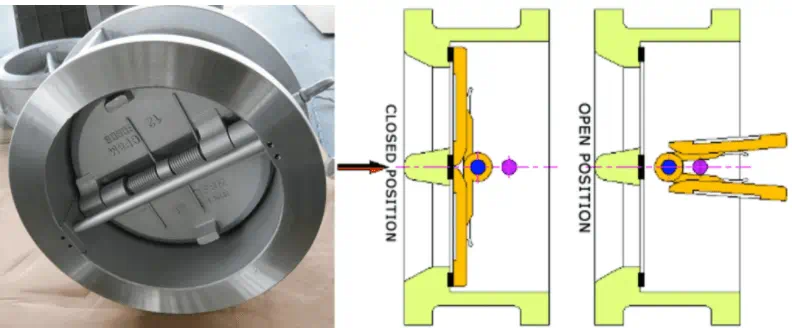

Other designs

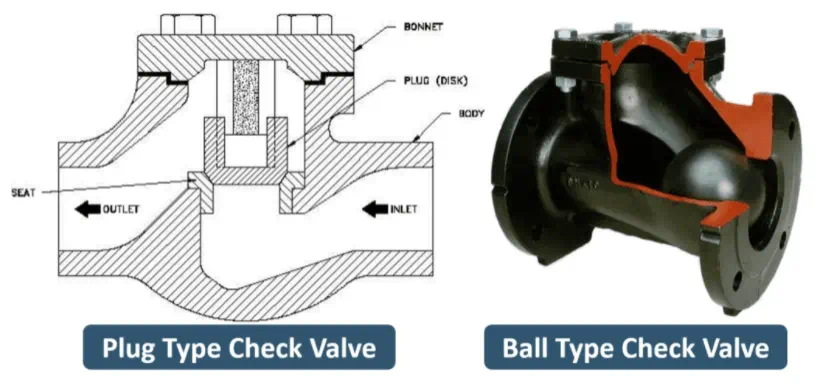

These are the three common check valves types, but there are other designs such as the dual plate types (butterfly check valve) and the ball type and plug type check valve.

Each of these has a unique way in which they operate; the butterfly check valve has two folding disks that move towards a centreline with the forward flow and close with reverse flow.

Image credit: Hard Hat Engineer

A ball type and plug type check valve work on the principle of gravity – when there is enough pressure in the flow the ball is lifted, then it drops the ball roll back to close the opening.

Image credit: Hard Hat Engineer

In-line check valves

An in-line component can refer to any useful object in a circuit that is attached to an adjacent fluid conduit – a check valve placed in a line. They are used to either enhance or upgrade an existing system.

Whereas a check valve’s main focus is to prevent the backflow of water into a system, an in-line check valve is used to prevent the backwards transmission of pressure.

For example, a check valve is generally installed after a pump in a series that makes use of an accumulator, a cold-water tank that facilitates water flow. The in-line check valve prevents stored energy from making its way back into the pump.

Excess energy that is stored in an accumulator can be damaging to a system, and it must be controlled for hydraulic systems to be safe and reliable.

How do you choose the right check valve?

Check valves are typically installed at the discharge point of a piping system to make sure that the fluid or matter that is being pumped out does not flow back into the system. There are a number of different check valves on the market and choosing the right one can be a difficult task.

Here are five things you should consider before choosing the right check valve:

Application

It sounds simple, but properly understanding what application your check valve needs to serve is critical in selecting the correct check valve.

Is it for a water sewage treatment plant? Is it handling corrosive materials? Is the discharge point below water? These are obvious conditions that can easily be overlooked when choosing a check valve.

A usual mistake that is made when selecting a check valve is choosing a valve that fits the system but cannot efficiently handle the flow conditions or the matter passing through the valve.

Water is one of the frequent matters that check valves handle and requires little special treatment. Most, if not all check valves, can handle water efficiently enough - depending on the flow rate.

But what if your check valve is handling corrosive chemicals? While a duck bill check valve is more than suitable to deal with water, can the rubber handle the corrosive chemicals, or will they destroy the check valve?

What if you need a check valve for a water sewage plant, a simple swing/flap check valve could do the task, but what will happen when sludge and debris clog up the metal hinge and stop it from being able to close?

Flow rate

Just as important as knowing what matter your check valve will be handling – it is important to know the rate of flow. Typically, this is recorded in terms of gallons per minute (GPM), gallons per hour (GPH), or litres per second (L/S).

If your application is producing a rate of flow greater than 8 feet per second flowing through the valve, there is an increased chance your valve will deteriorate quicker – regardless of whether you are using a rubber-seated valve or metal-seated valve.

Inlet pressure

Understanding your inlet pressure will help you select which style of check valve best suited for your needs. It can help you decide whether you need an in-line check valve, a slip-on check valve or a flanged style check valve.

Deciding on which one you need to use will depend on where the check valve will be located in your pumping system.

Back pressure

Back pressure is the differential pressure between the inlet and outlet pressures of your system. You need to know if your check valve can withstand the back pressure that it could be exposed to.

For example, say you have a valve installed at the end of a pipe, and it is pumping water in the Thames river. When the Thames water level rises, how deep with the valve be submerged? When the water rises above the valve, that is the point at which back pressure is created. Can your valve cope with that amount of back pressure?

Location

Is your valve discharge point above or below ground? Is it submerged? Is it in a hot sandy country, or on a cold desolate one?

Again, these appear to be obvious conditions that we could never forget – but properly understanding the location of the valve will have a massive impact on the check valve you need to select.

Sand can corrode a metal valve; the sun can deform a rubber duck bill check valve (always ensure you use the proper elastomer to prevent this) and ice can freeze a swing/flap check valve open.

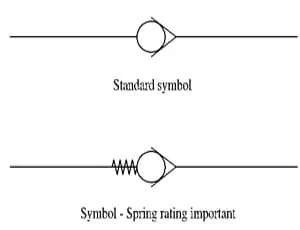

The check valve symbol

Check valves provide one-way flow, and it is vital to install them in the correct alignment.

Below are two check valve symbols: the top one, flow is allowed from the bottom of the pipe but not the other way, the bottom, the valve will only allow flow when the pressure at the bottom is greater than the pressure at the top (taking into account the rating on the spring).

Image credit: Valve Products

Materials Matter

It could be hard to see the relationship between Formula One and check valves, but there is a connection: elastomers, or rubber. If you want to win Formula one you need to understand tyres, specifically the rubber they use.

Cal Hayes believes he is more in the business of designing new compatible rubbers for different types of chemicals in check valves than designing new check valves.

“There are so many different types of elastomers that can do so many different things. If you look at NASCAR, of if you look at F1, there are people that get paid millions of dollar per year to come up with a better tyre that lasts longer - it’s the same with the check valve.”

The material that is used in the construction of a check valve can determine how long it will last for and what matters it can deal with. In the case of duck bill check valves, the elastomer can have a major impact on the quality, efficiency and life span of the valve.